DOE-Driven Optimization of ABS FDM Warpage

ABS is strong and heat-resistant, but it’s notoriously prone to warpage in FDM due to thermal shrinkage and uneven cooling. In this project, we tackled warpage as a measurement + statistics + process optimization problem instead of trial-and-error tuning.

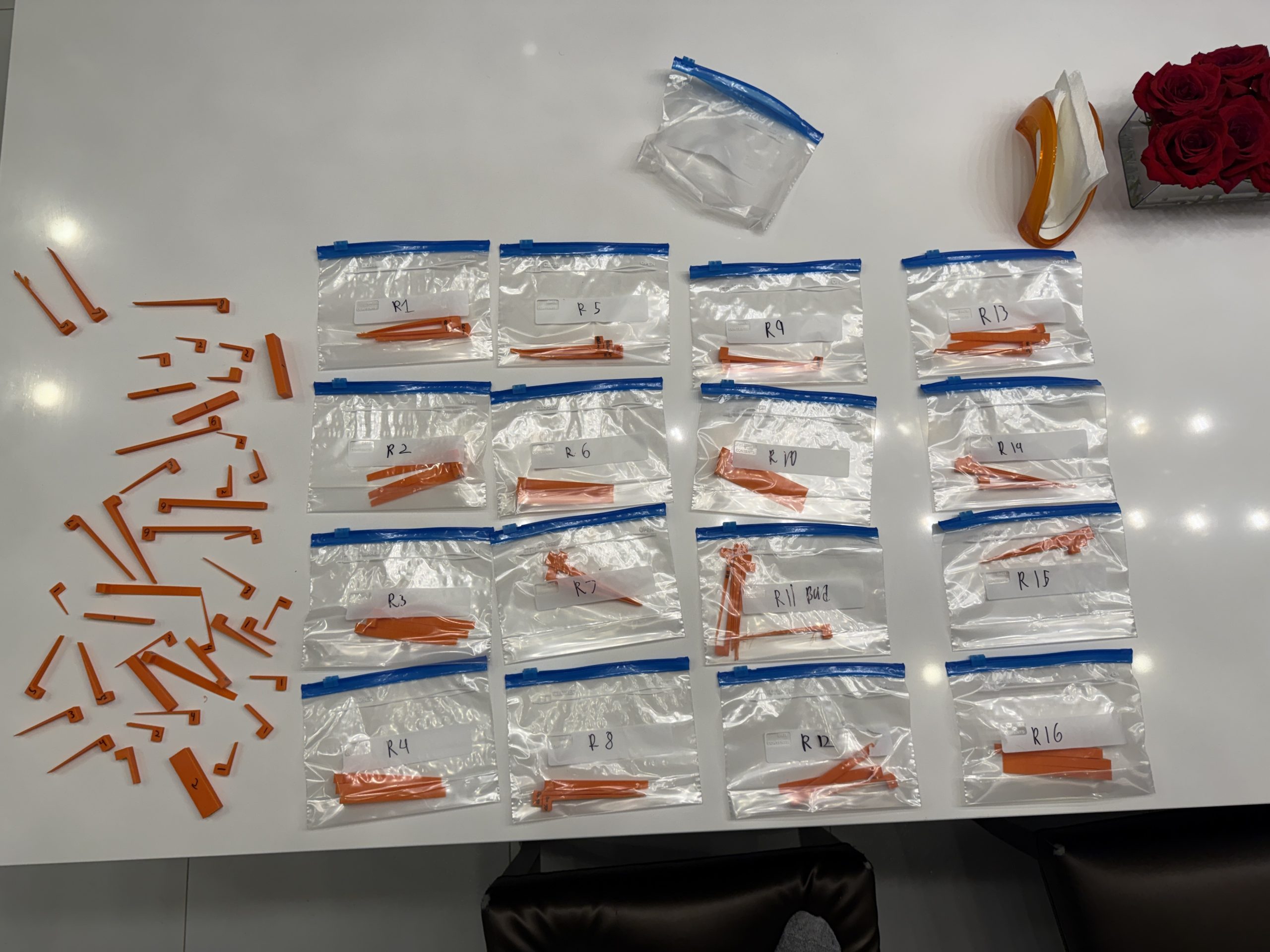

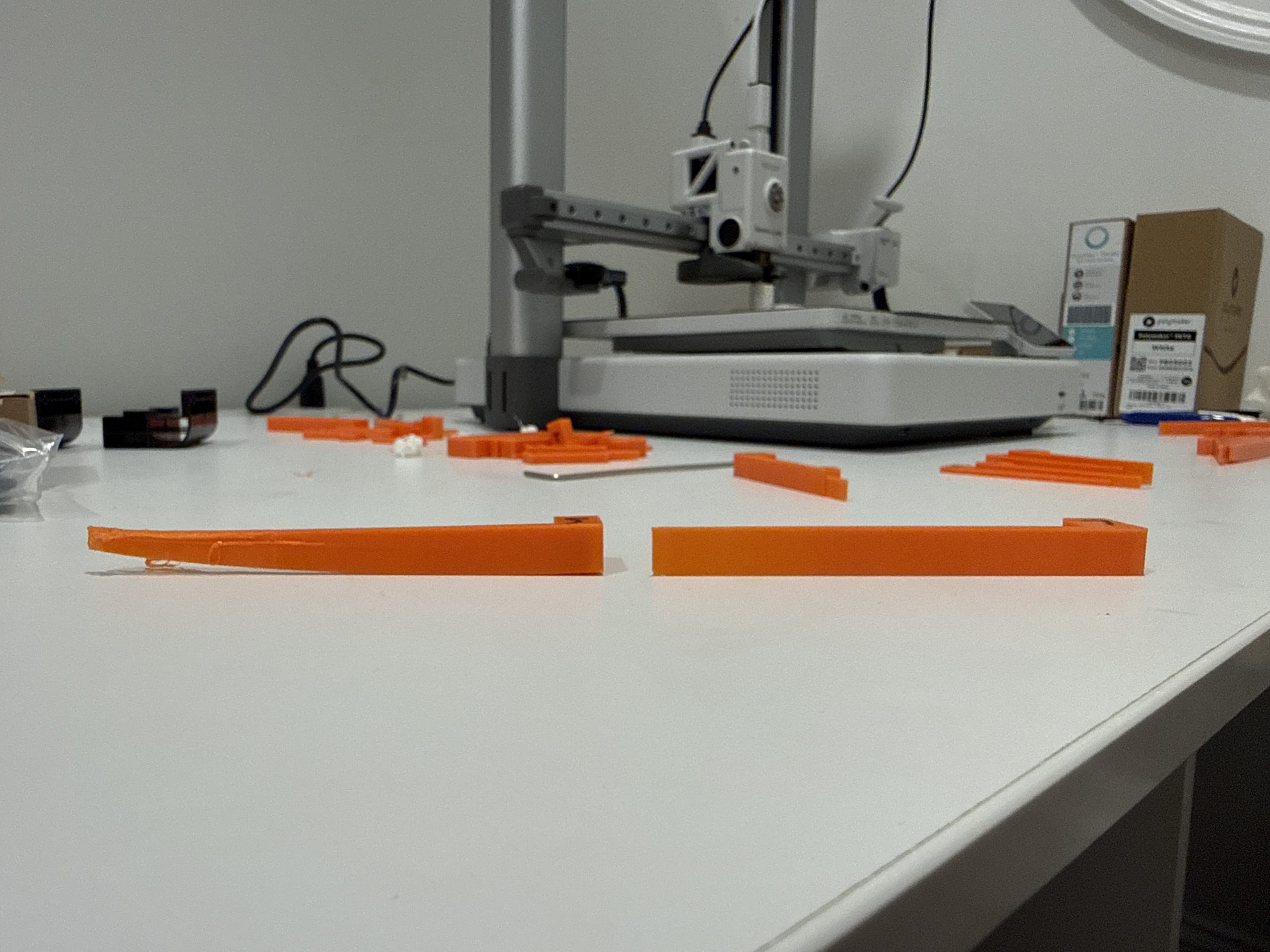

We designed and executed a Resolution V fractional factorial DOE to quantify the effects of five print parameters on warpage: print speed, nozzle temperature, bed temperature, wall count, and cooling fan power. To make the experiments meaningful, we iterated on the test part design until we had a warpage-sensitive geometry that produced consistent, measurable deformation.

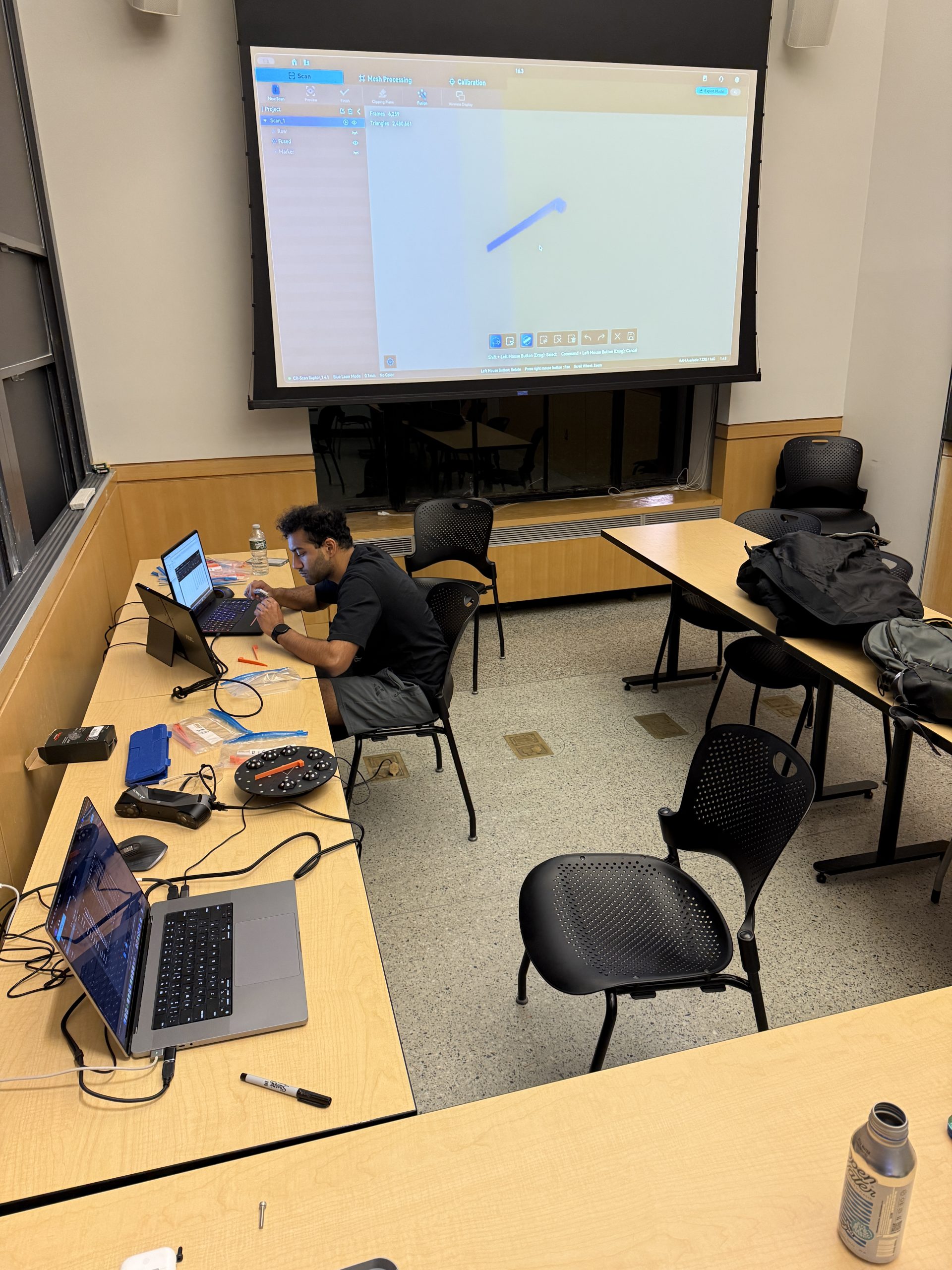

For metrology, we used non-contact 3D scanning (point cloud to mesh), cleaned the scan data, and then quantified warpage digitally by aligning the part to reference surfaces and measuring the tip displacement relative to the build plate plane. With clean measurements in hand, we built a regression/ANOVA model to identify statistically significant main effects and interactions, and used curvature testing to capture a nonlinear print-speed effect.

Finally, we used the fitted model to optimize print settings and ran confirmation prints to validate the result. The optimized parameters produced a warpage that was statistically indistinguishable from zero, showing that a data-driven workflow can dramatically reduce deformation in ABS printing and turn a frustrating print failure mode into a controllable process.

The full experimental setup, statistical analysis, and results are documented in the full project paper, while the project presentation provides visual context for the geometry design, scanning workflow, and warpage measurements. A gallery at the bottom of the page highlights key stages of the process, including part iterations, printing, scanning, and analysis.

Meet The Team

Benjamin Breslov

Nishant Chitluru

Valeria Ferrer Morillo

This project was a true team effort between Valeria, Nishant, and myself. We contributed equally across all stages of the work, from experimental design and part iteration to printing, measurement, statistical analysis, and optimization. We worked closely throughout the project, shared ownership of decisions and execution, and built on each other’s strengths as challenges came up. Beyond the technical outcome, it was genuinely a great team to work with, and the collaboration played a big role in the success of the project.

Gallery