ECM Build

Inspiration

While taking an Advanced Manufacturing class, one of the topics we studied was electrochemical machining (ECM). I found the process fascinating, but the class was entirely theory-based — we never actually interacted with machines like this. Since commercial ECM systems are expensive and inaccessible, I decided to build one myself as a solo project. My initial goal was simply to create a fully functional ECM machine I could personally use, proving that the concept wasn’t as out of reach as it seemed.

As I developed the project, I realized it could serve a much larger purpose: not just as a personal tool, but as a hands-on educational platform. I proposed the idea to my professor, who supported it fully, and I went on to design both the machine and the accompanying curriculum. What began as an individual project has since become part of the course, allowing other students to engage with ECM in practice rather than just theory.

How I built it

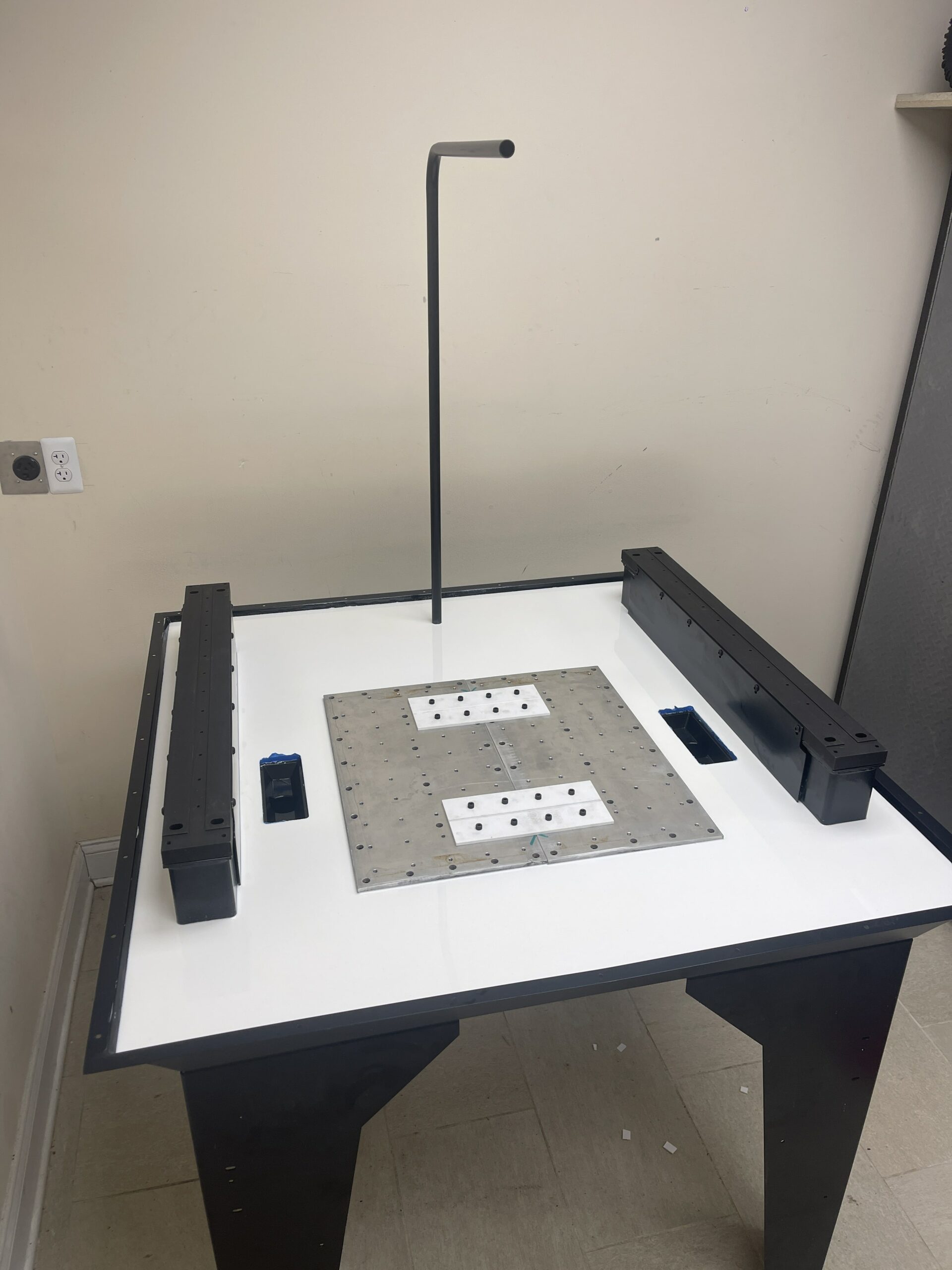

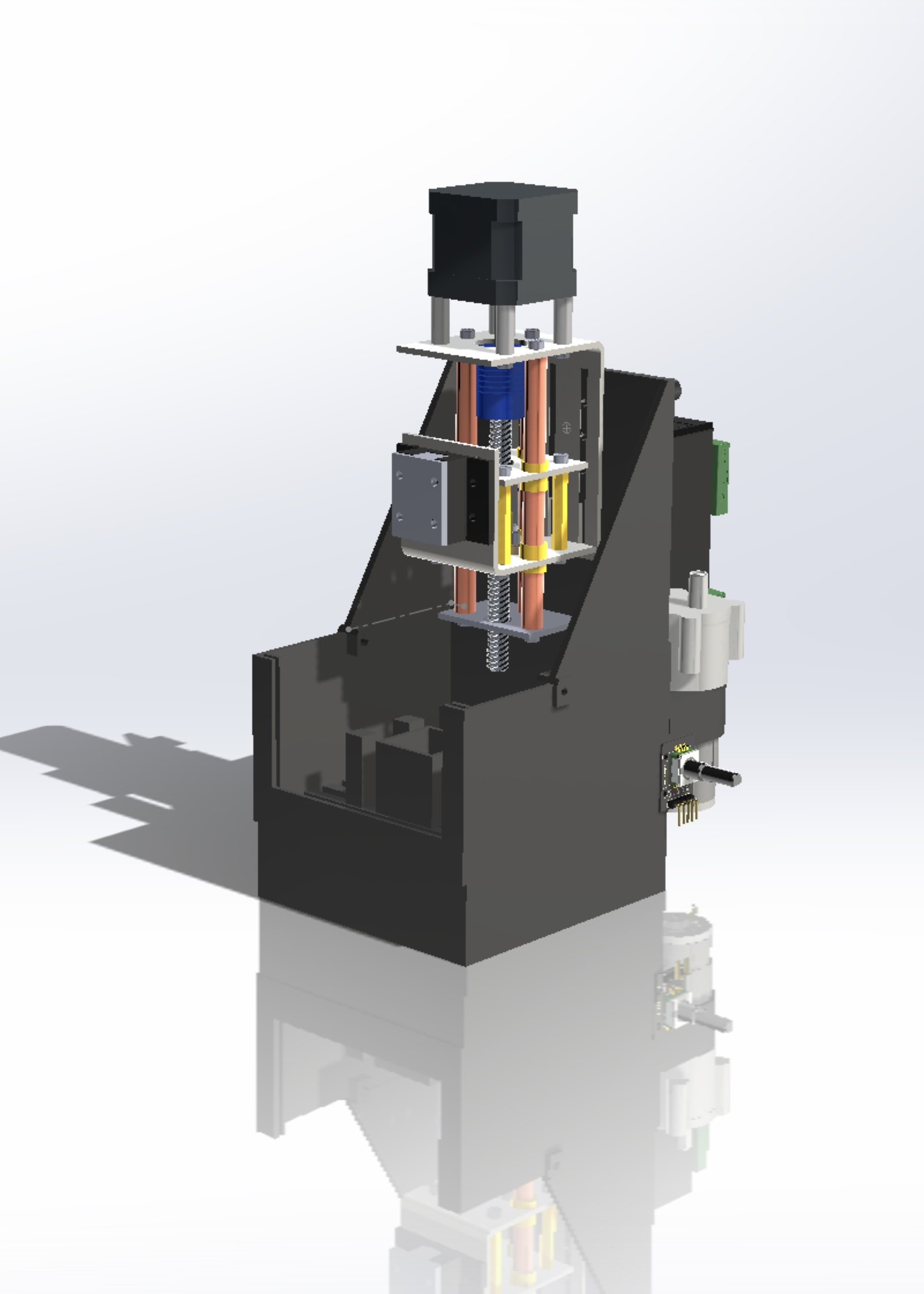

The machine was designed from the ground up to be both accessible and reproducible. I chose to make the entire frame 3D-printed because a 3D printer is one of the most common tools available to at-home makers. Using printed parts with brass inserts and stainless steel hardware provided durability while keeping the build approachable.

For motion, I used a pre-built Z-axis driven by a NEMA 17 stepper motor; simple, reliable, and easy to source. The electrolyte management system uses a straightforward pump design that circulates fluid through and around the electrode, with modularity to put in any cutter the user wants. An Arduino Nano handles motion, pumping, and power delivery, which was chosen because of its low cost, wide availability, and ease of programming.

First Cuts

For the initial tests, I used a 1/8-inch aluminum flat bar, and the machine was able to cut through it with ease. The results clearly demonstrated that the system works as intended, removing material cleanly without heat-affected zones or tool wear. While the cut quality was not perfect, that is expected in early trials and can be improved over time through parameter tuning, flow optimization, and refinements to the setup. These first successful cuts validated the design and confirmed that a low-cost, accessible ECM machine can reliably perform real machining tasks.

Next Steps

While the machine was able to cut through aluminum with no problem, the surface finish and overall cut quality still leave room for improvement. My next focus is on experimenting with tooling design and optimizing electrolyte flow paths to achieve cleaner, more consistent results. Beyond refining cut quality, I also plan to expand the system into a full three-axis machine. This upgrade would allow for machining of more complex shapes and geometries, making the system an even stronger, more versatile platform for makers.