Robotic Hand

This was a solo project I completed in high school as a way to gain early exposure to coding and robotics. I designed and built a sensor glove that used strain gauges to detect finger movements and translate them onto a robotic hand. I handled all of the wiring and programming, learning how to interface sensors with an Arduino to control motion in real time. While I originally designed my own robotic hand to 3D print, the COVID-19 shutdown prevented me from accessing a printer, so I used a prebuilt robotic hand instead to complete the project.

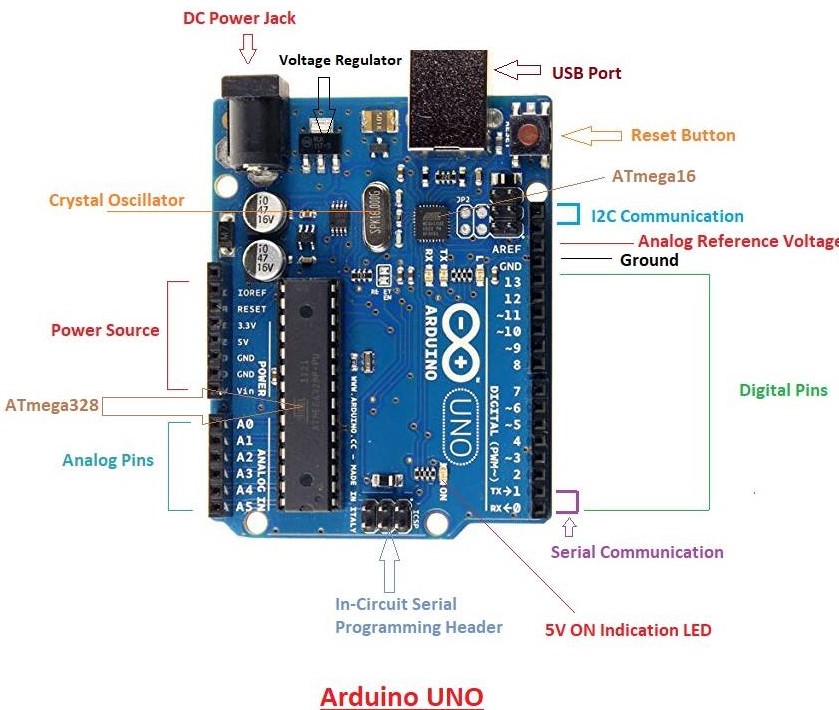

Arduino

The Arduino prototyping platform is the heart and the brain of this project. We used it to sense the analog signals coming from the flex sensors on the glove and translate them into servo movements.

The Glove

We took an ordinary work glove and connected flex sensors to each of the five fingers. Once calibrated, the flex sensors sent a restive value, which was translated by the Ardino to an exact finger position.

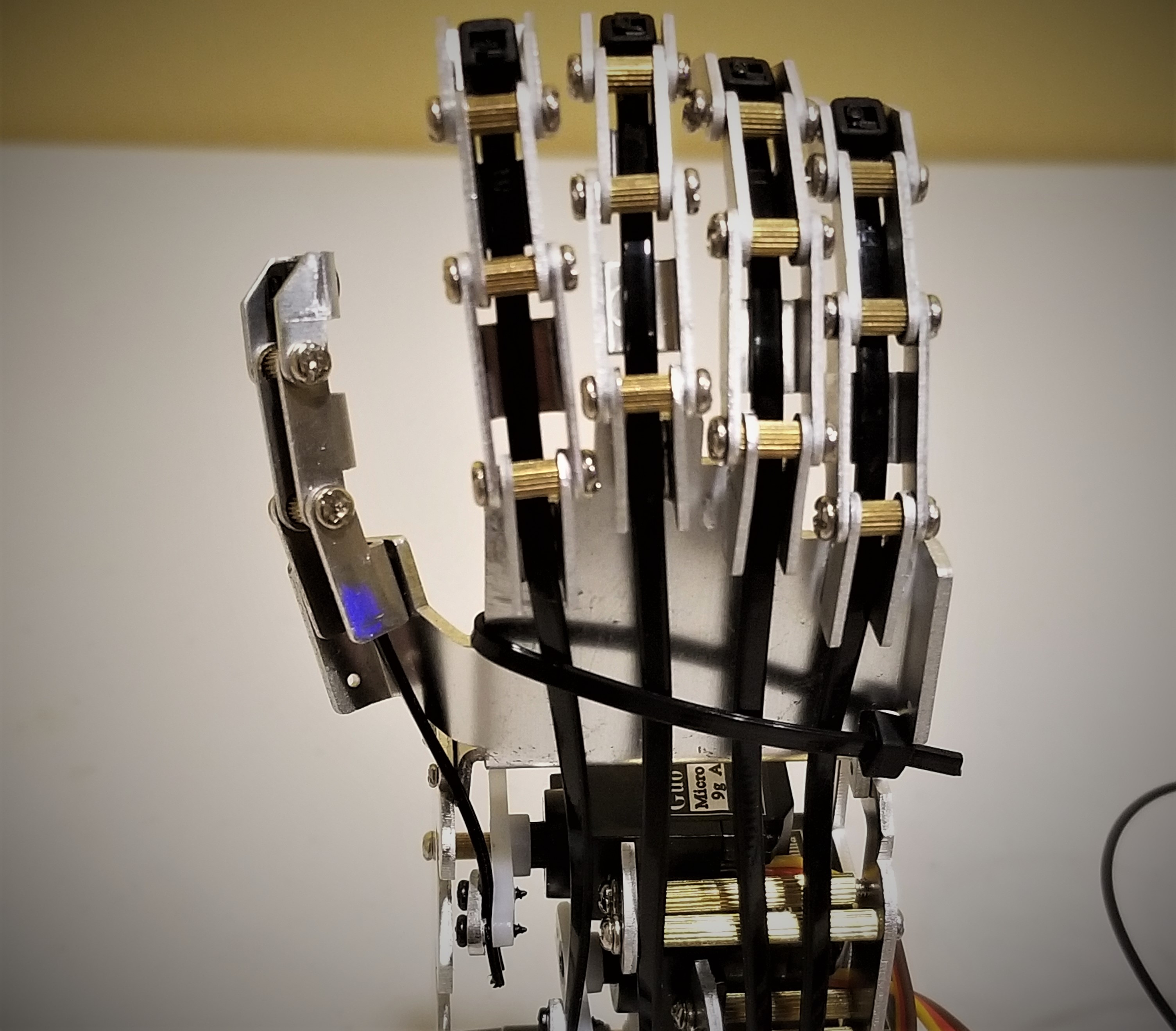

Robotic Hand

The mechanical hand uses the signal from the Arduino to activate the servos for each finger. The higher the signal from each flex sensor, the more force is generated by each servo.

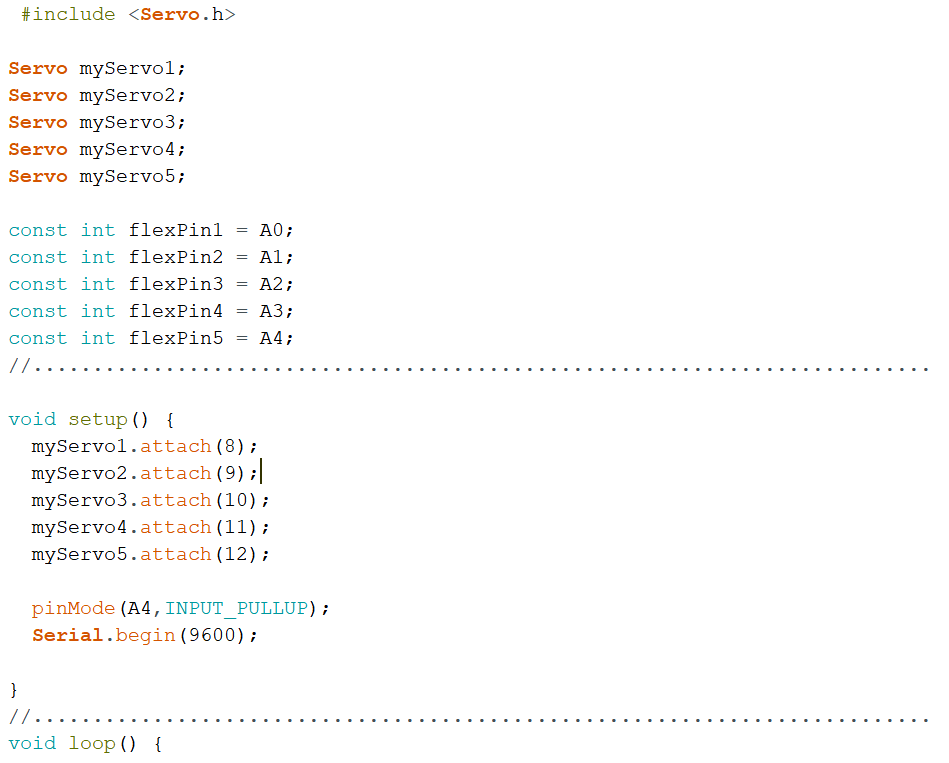

The Code

Python code was used to program the Arduino. Python is an interpreted, high-level, general-purpose programming language. Each of the fingers had to be programmed and calibrated independently.

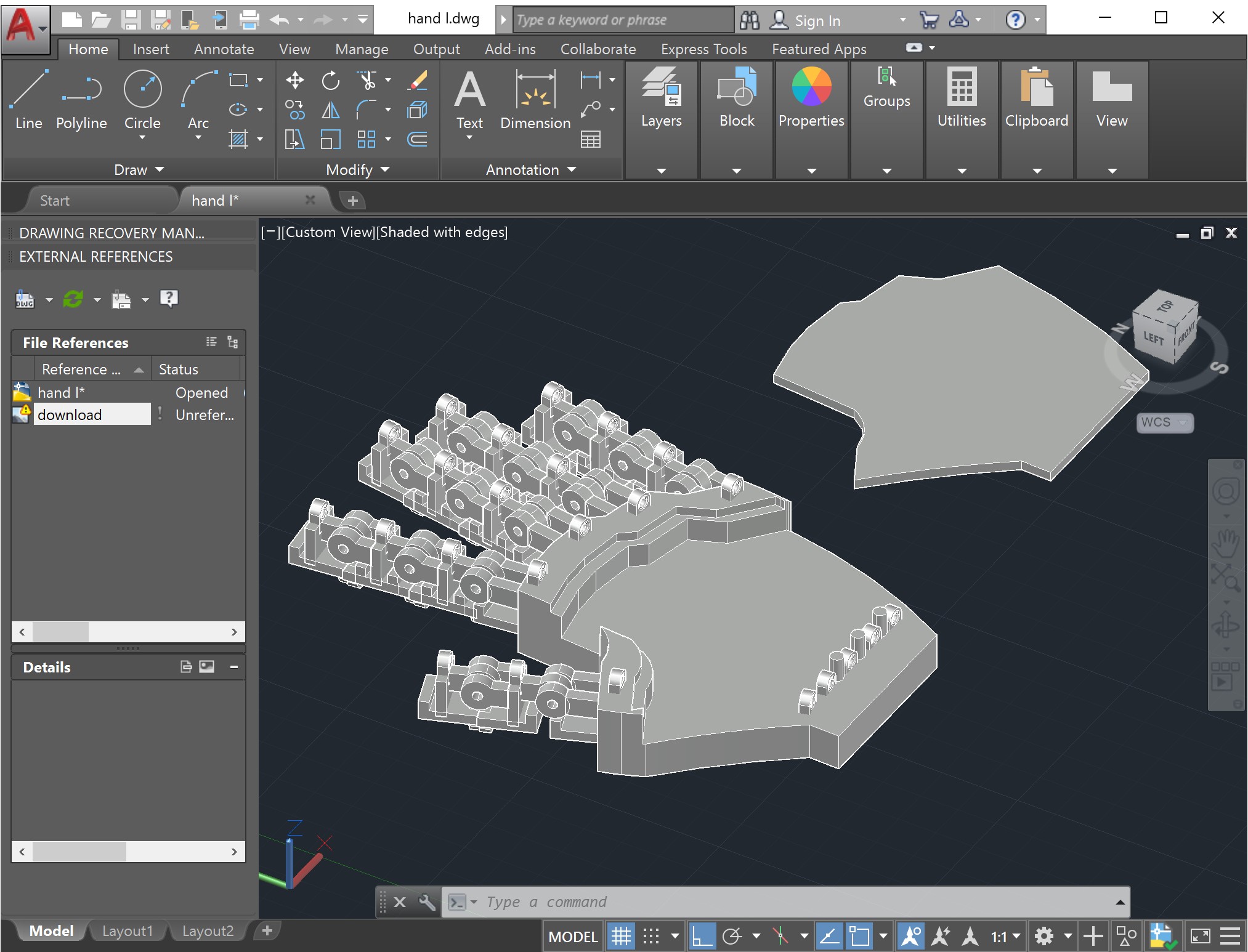

The CAD

For the next stage of the project, we used Autocad to design a new version of the hand, which will be 3D printed soon. Having our own design and 3D printing capabilities gives us more options to add sensors, such as touch, as well as add wrist rotation in the future.