Mass Production Of Rc car wheels

Project Introduction

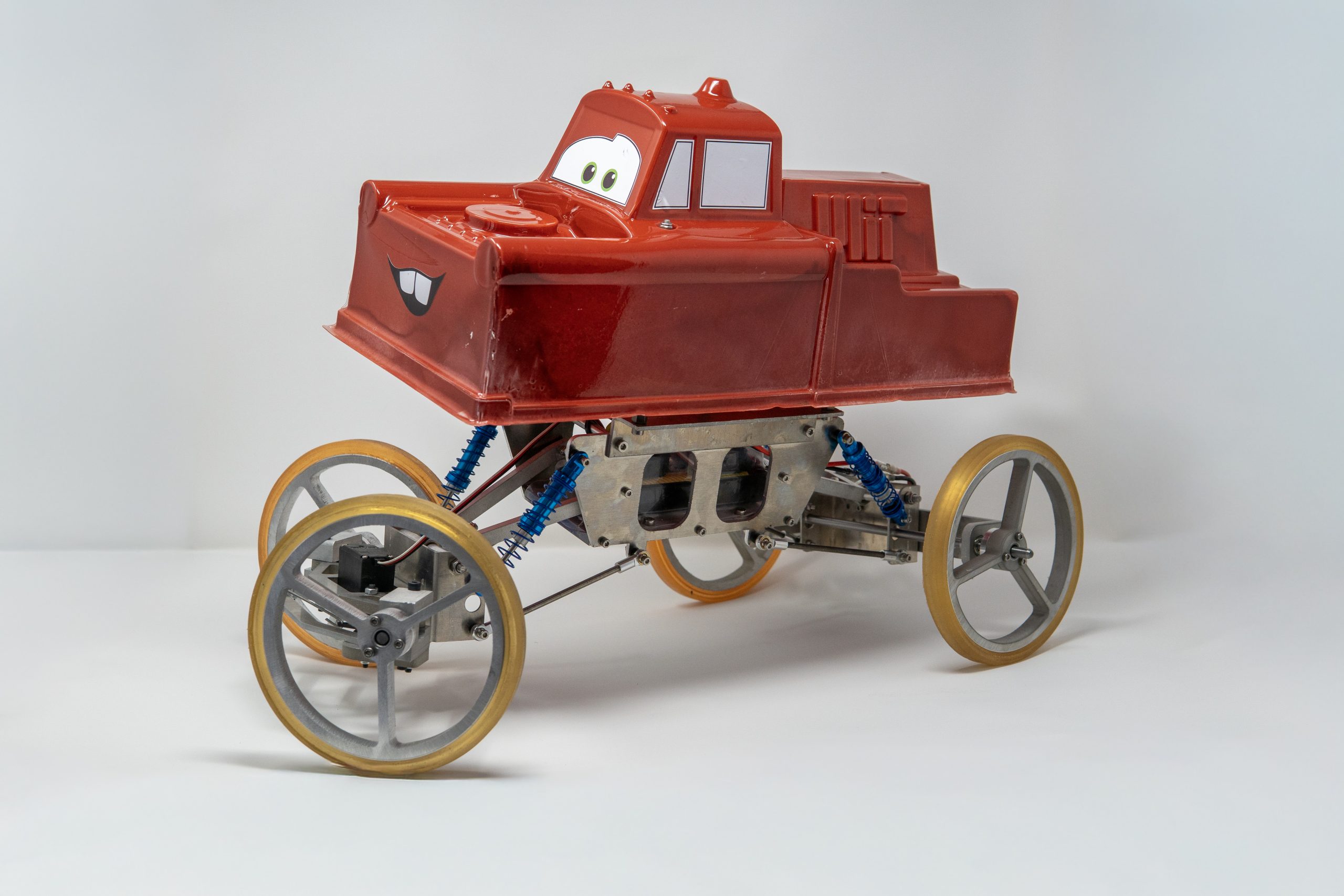

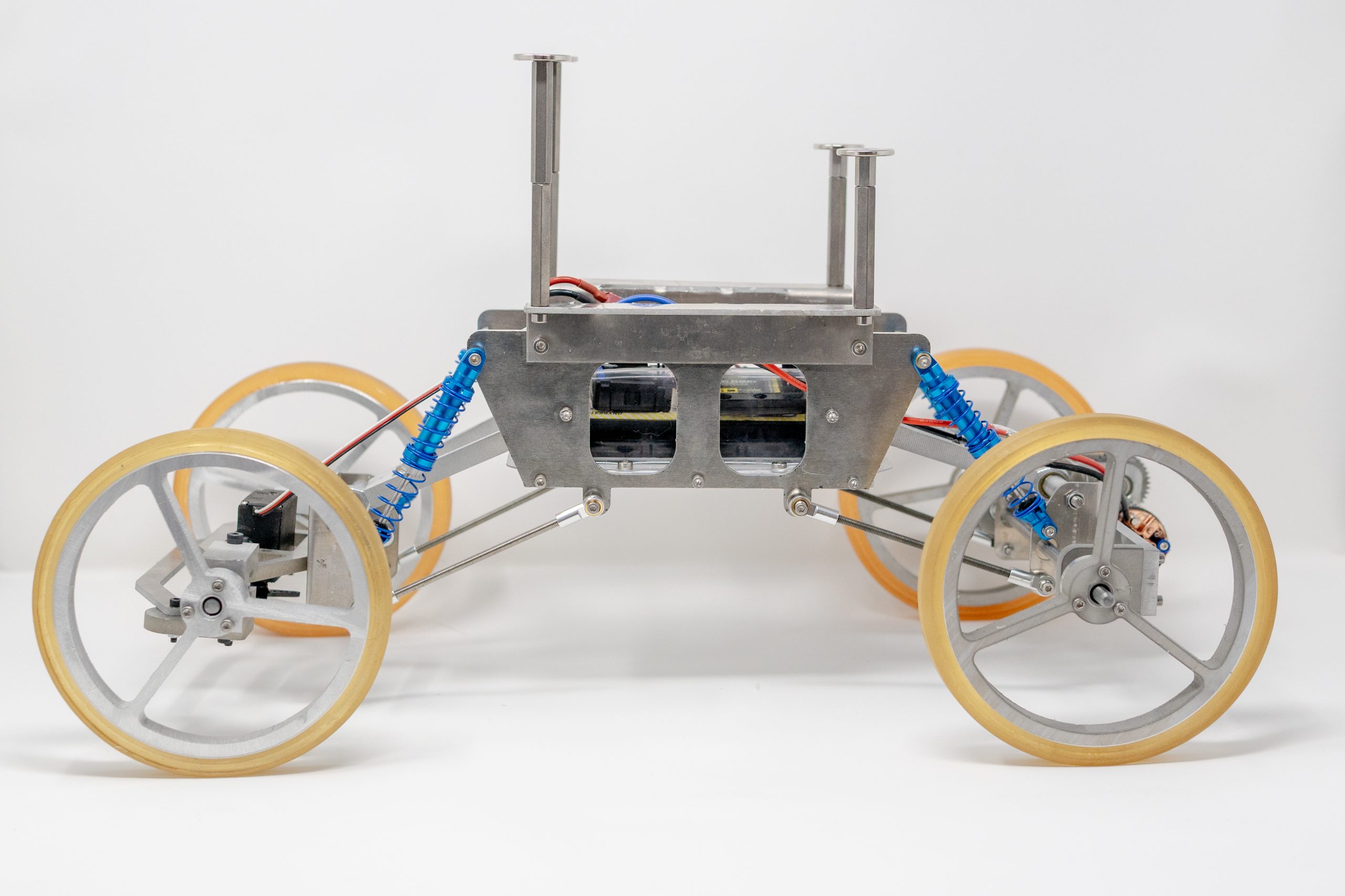

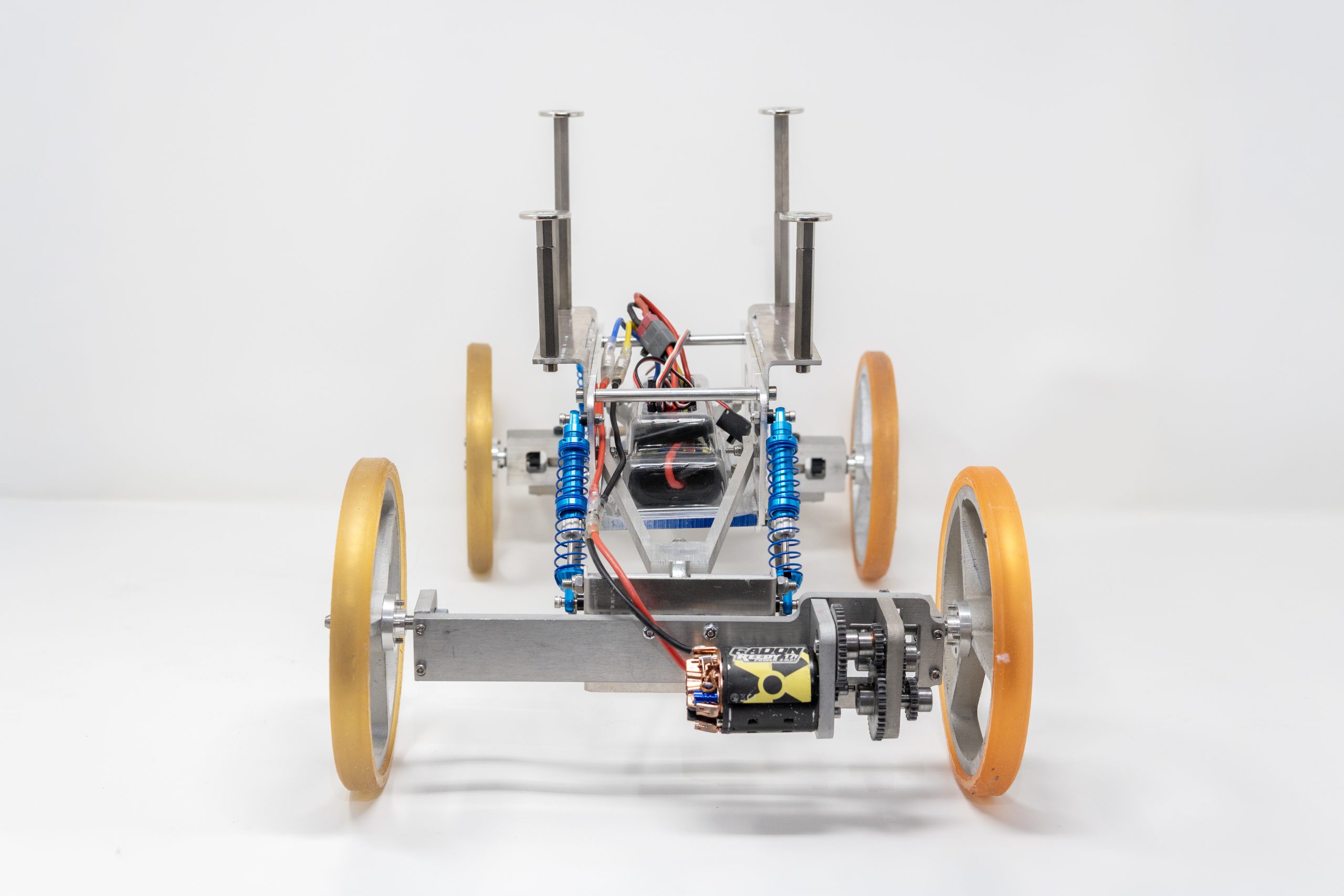

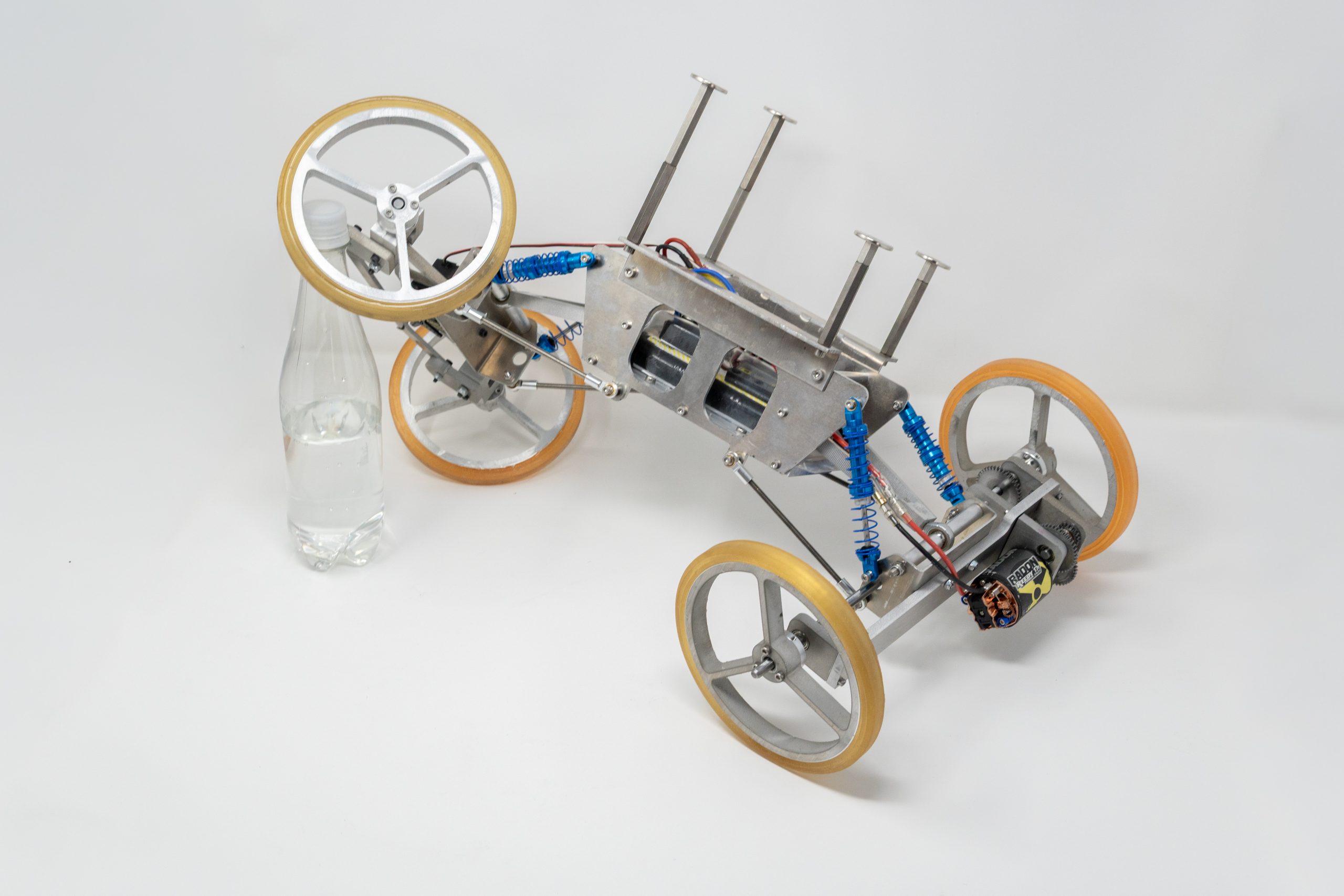

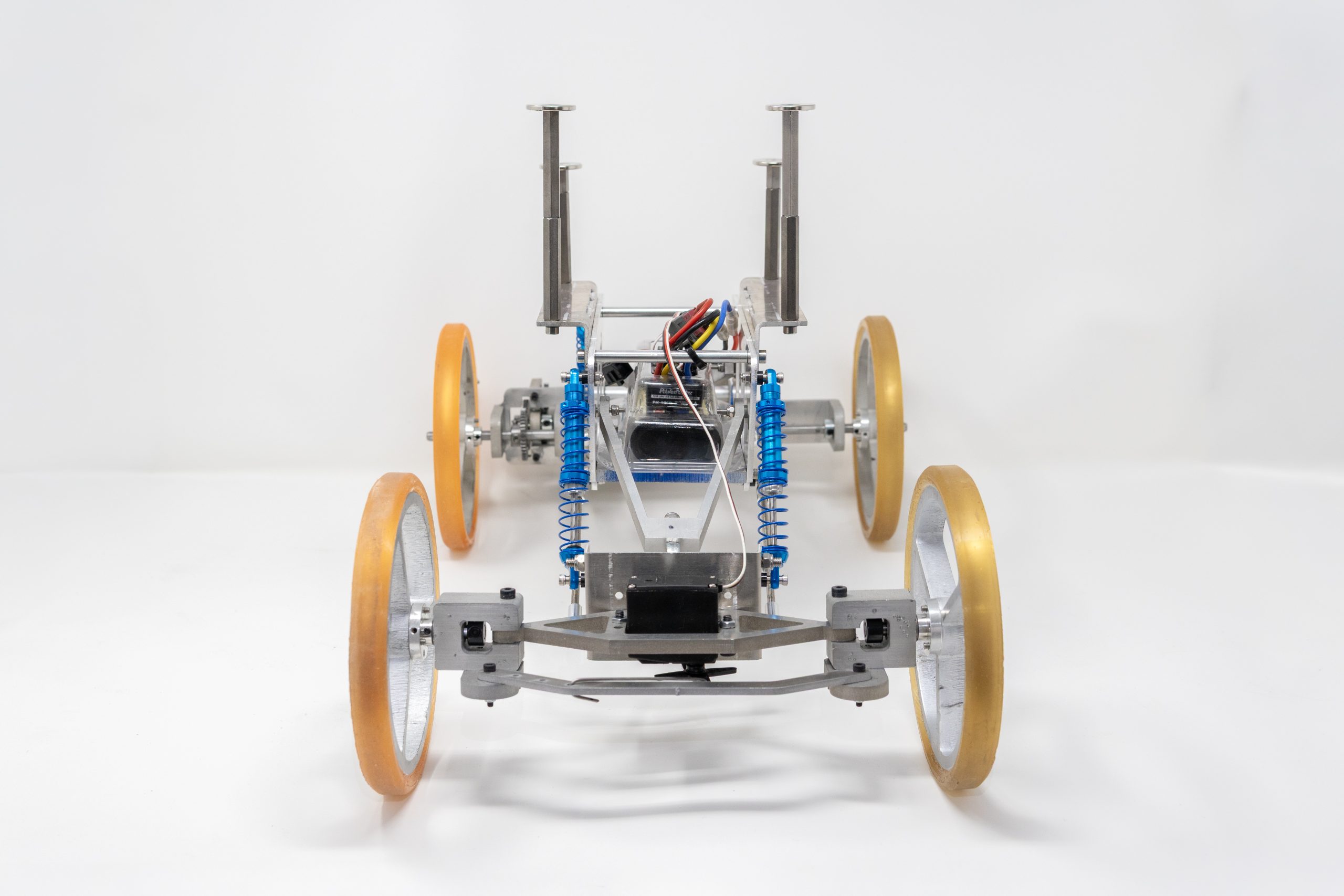

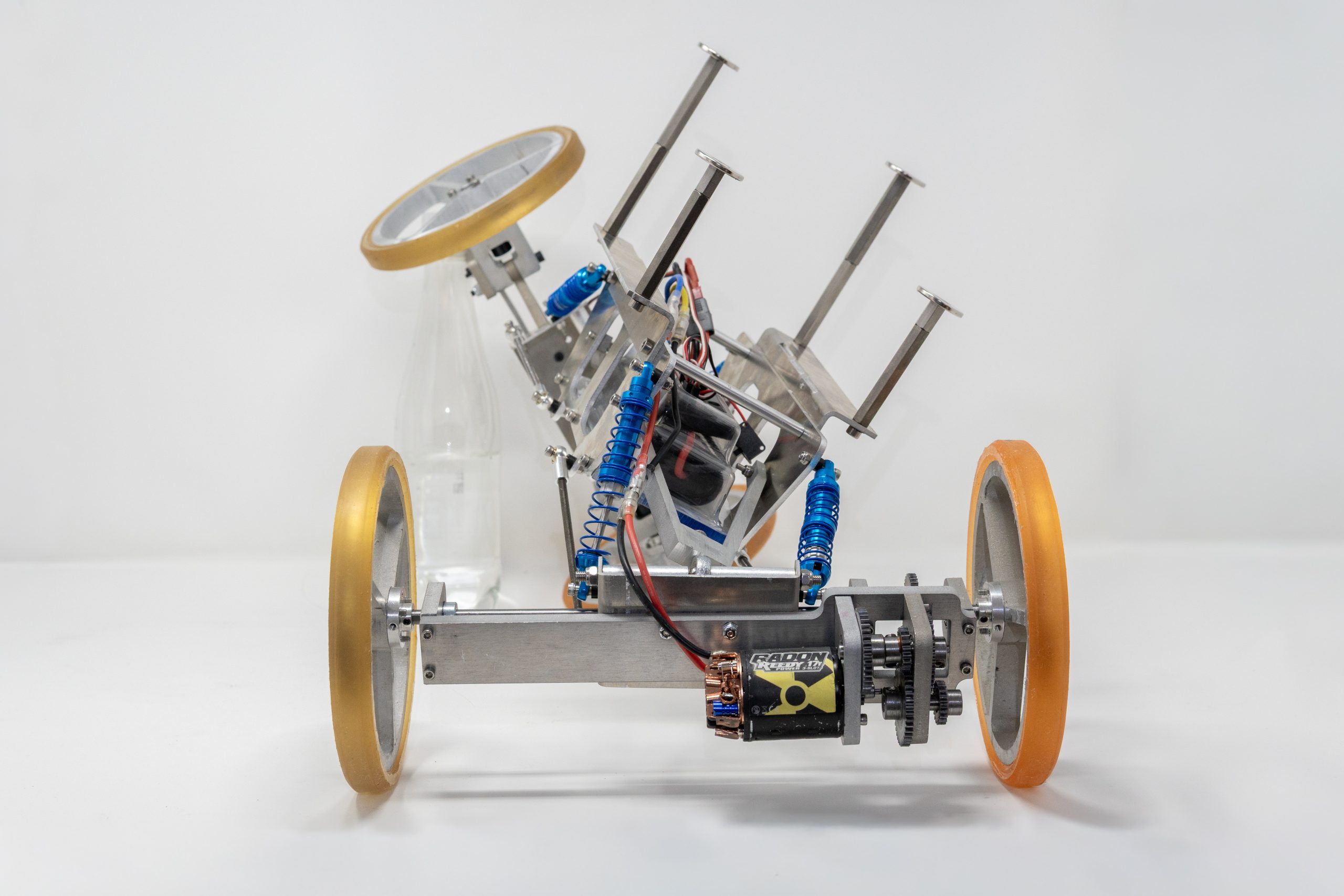

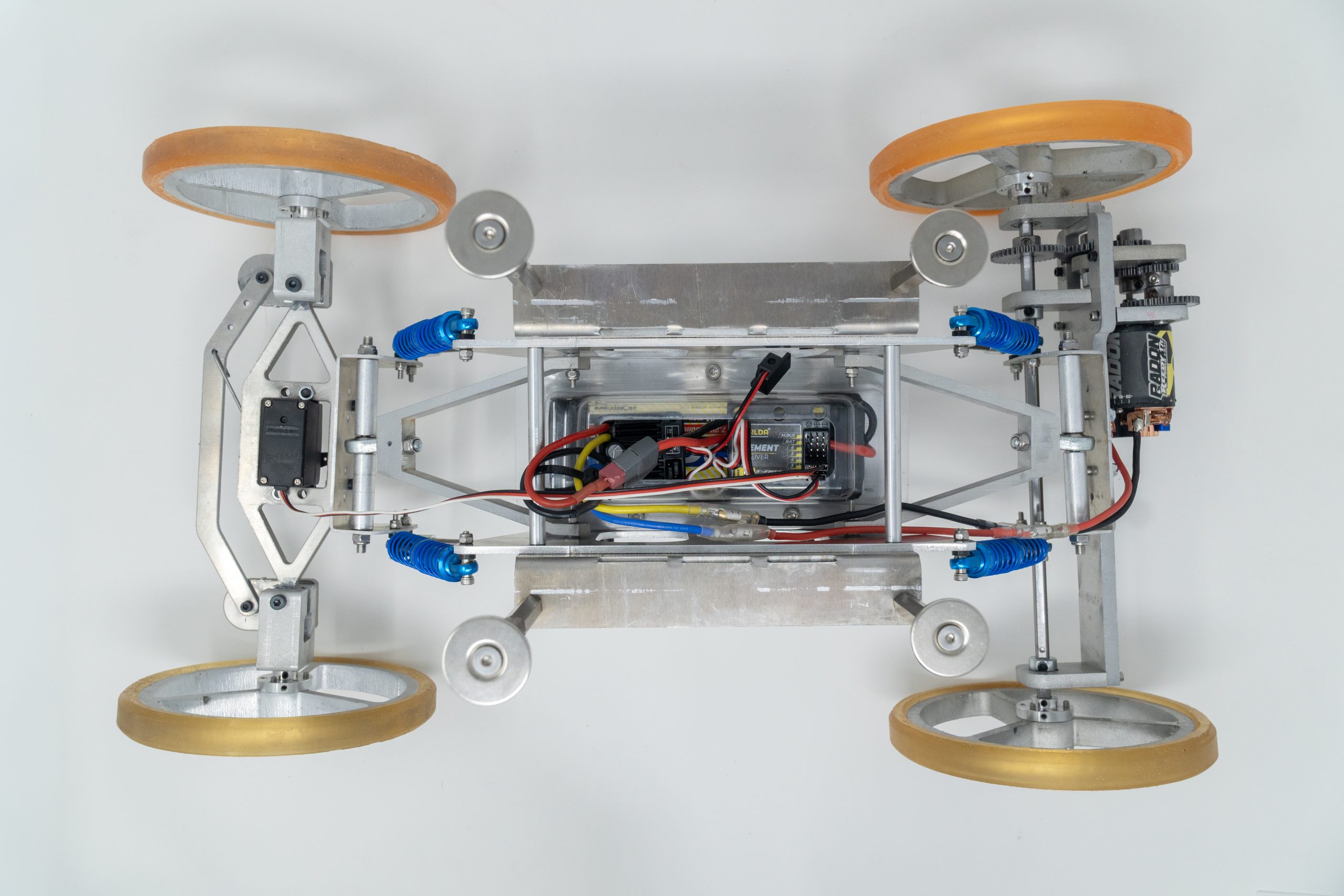

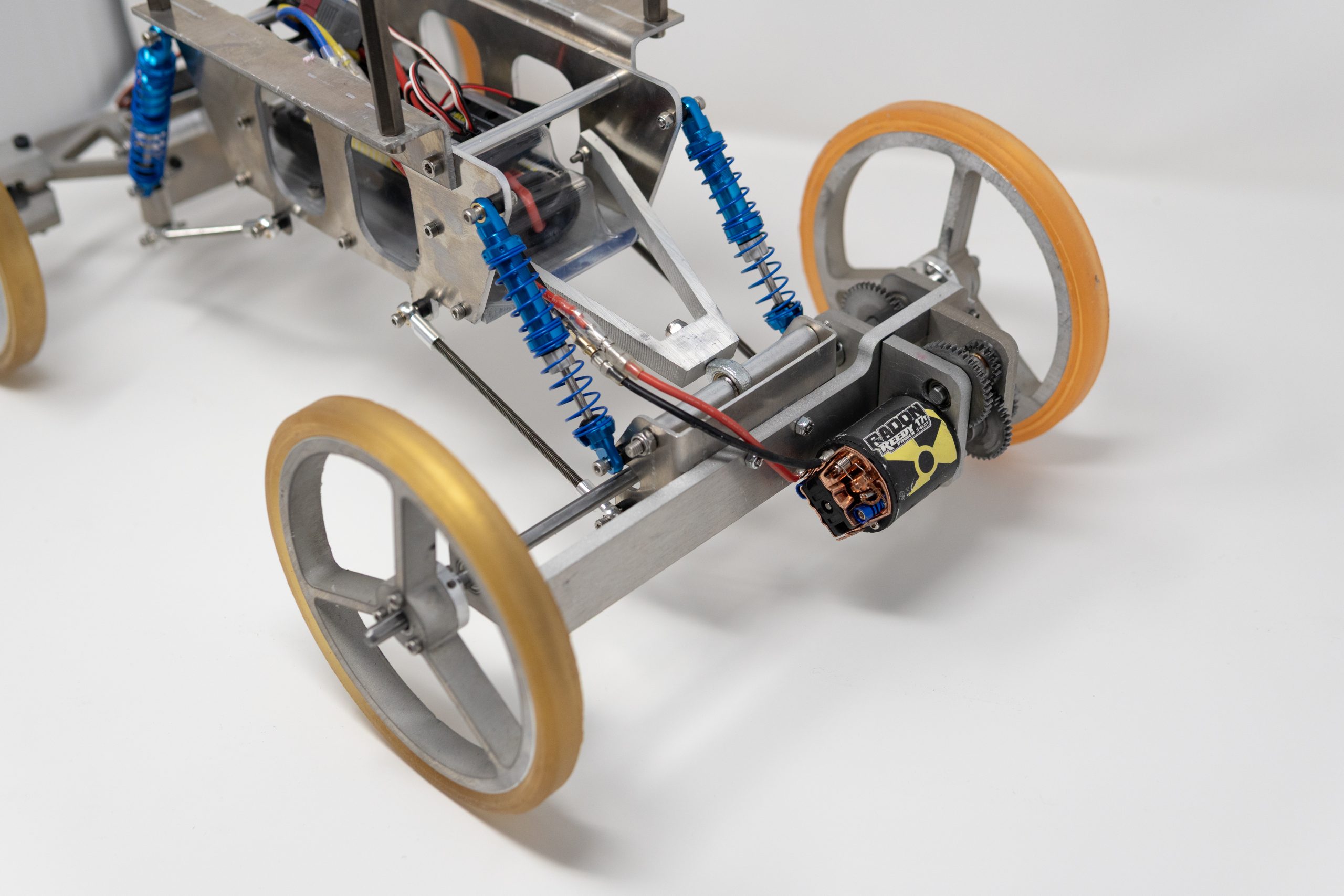

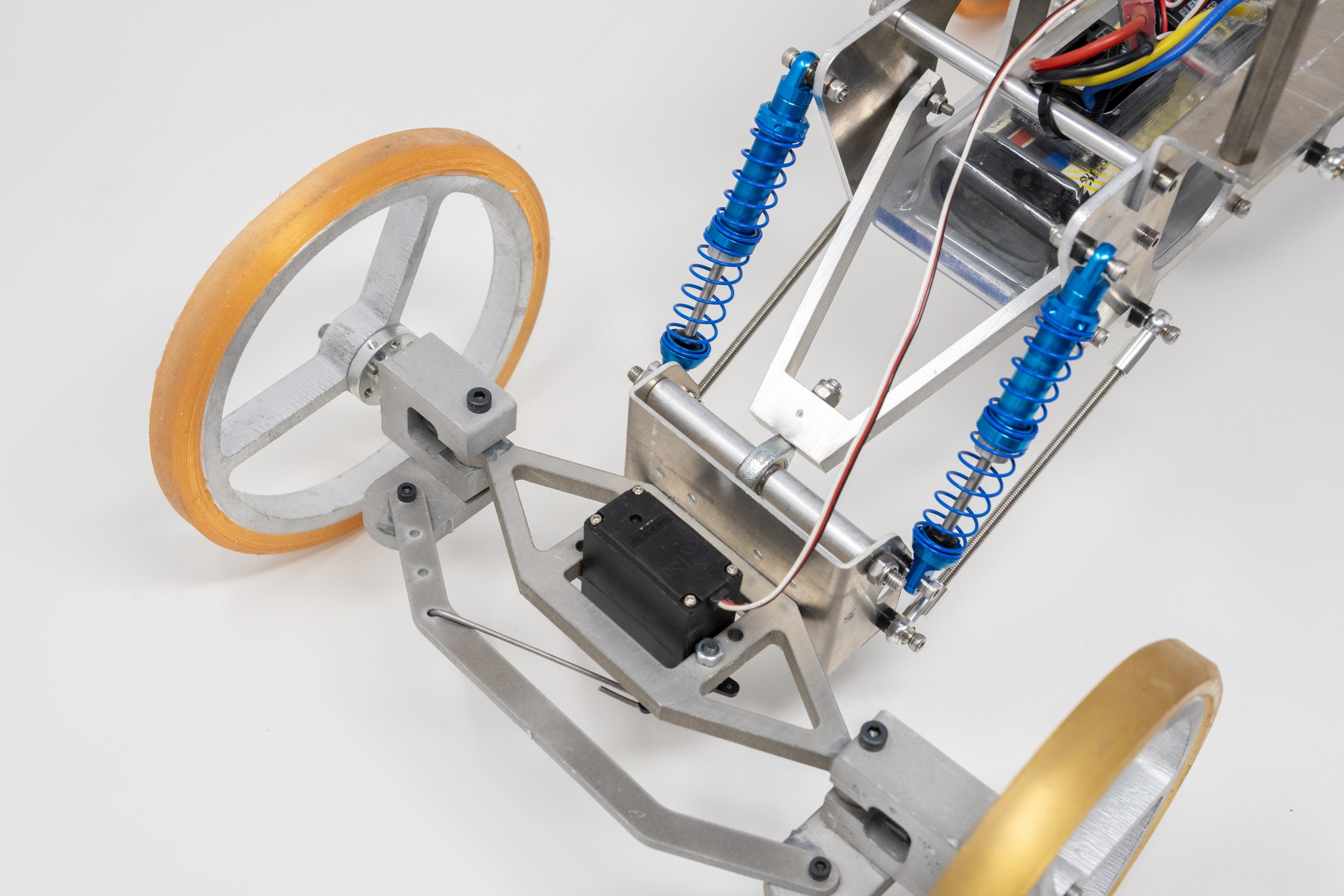

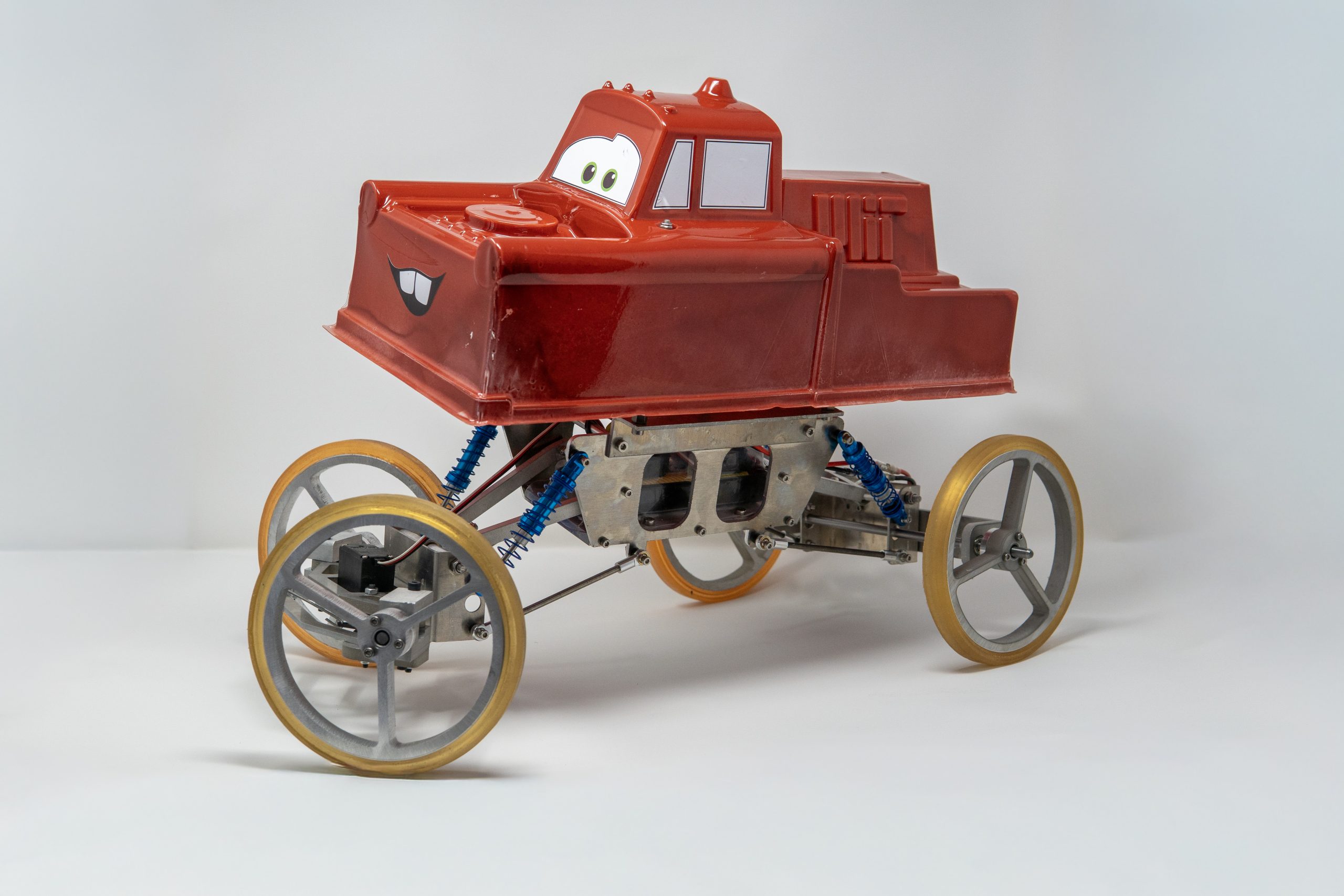

While studying at MIT in the Advanced Manufacturing and Design program, I took 2.810 Manufacturing Processes and Systems, a course that applied manufacturing theory to a real, production-scale project. The semester culminated in a team effort to design and mass-manufacture an RC car, not as a one-off prototype, but in quantities large enough for every student to receive a finished vehicle. The class was divided into multiple specialized teams, including steering, suspension, drivetrain, chassis, cover/electronics, and wheels, all working in parallel to bring the full vehicle together. I was part of the wheels team, responsible for designing and producing 160 identical wheels using only traditional manufacturing methods, with additive manufacturing intentionally excluded. This was arguably one of the most demanding roles, as it required the highest part count and strict consistency across every unit. The constraints pushed us to think carefully about scalability, process planning, and design for manufacturing, while still prioritizing performance and aesthetics, resulting in a component and production approach that closely mirrored real-world manufacturing challenges.

My Role

- Co-developed the wheel and tire design in close collaboration with Nish, working side by side throughout the design process to refine geometry, performance, and manufacturability.

- Led the development of the wheel manufacturing strategy, defining the overall process flow from waterjet cutting through reaming and CNC lathe finishing.

- Executed the second half of the wheel manufacturing process alongside Nish, including reaming critical features and CNC lathe operations to finish the outer wheel profile and tire retention geometry.

- Designed and fabricated all custom tooling and fixtures used in production, including the CNC lathe wheel jig and the D-shaft divot drilling jig, manufacturing them in-house using the mill, lathe, and 3D printing.

Meet The Team

From left to right, the team is shown with each member contributing to the manufacturing of the RC car wheels. Valeria and Nour were responsible for casting the tires. Nish and I handled finishing operations on the wheels, including machining the outer profiles on the lathe and reaming critical holes to ensure proper fits. We were also responsible for making all jigs and tooling needed. Ayush and Marc prepared the wheel blanks by waterjetting them from an aluminum sheet and performing the initial part preparation before passing them on for finishing. Wade, the lab manager, supported the team throughout by assisting with machinery, setup, and process guidance as needed. The wheel design was developed collaboratively, after which the labor was divided to handle the scale of production.

Beyond individual roles, this project was only possible because of how well the team worked together. While responsibilities were divided to handle the scale of manufacturing, every major decision was made collaboratively, and the final outcome reflects that shared ownership. Each person brought different strengths to the table, and the project benefited directly from that balance. A special thank you goes to Wade, whose dedication went far beyond managing the lab. He consistently made time for every team, helped troubleshoot problems at all hours, and brought an energy that made the entire experience more rewarding. His support, patience, and commitment played a major role in the success of this project, and it would not have come together the way it did without him.

Project Planning

From the outset, the scale of the project shaped every planning decision. Producing 160 wheels within a limited semester timeline required the design to come together quickly and cleanly, without sacrificing performance. The team moved rapidly through early brainstorming and converged on a core wheel and tire concept within the first week, followed by a second week of focused prototyping and testing. Multiple wheel geometries and tire profiles were evaluated in parallel, allowing the design to mature quickly while still leaving room for refinement before committing to production.

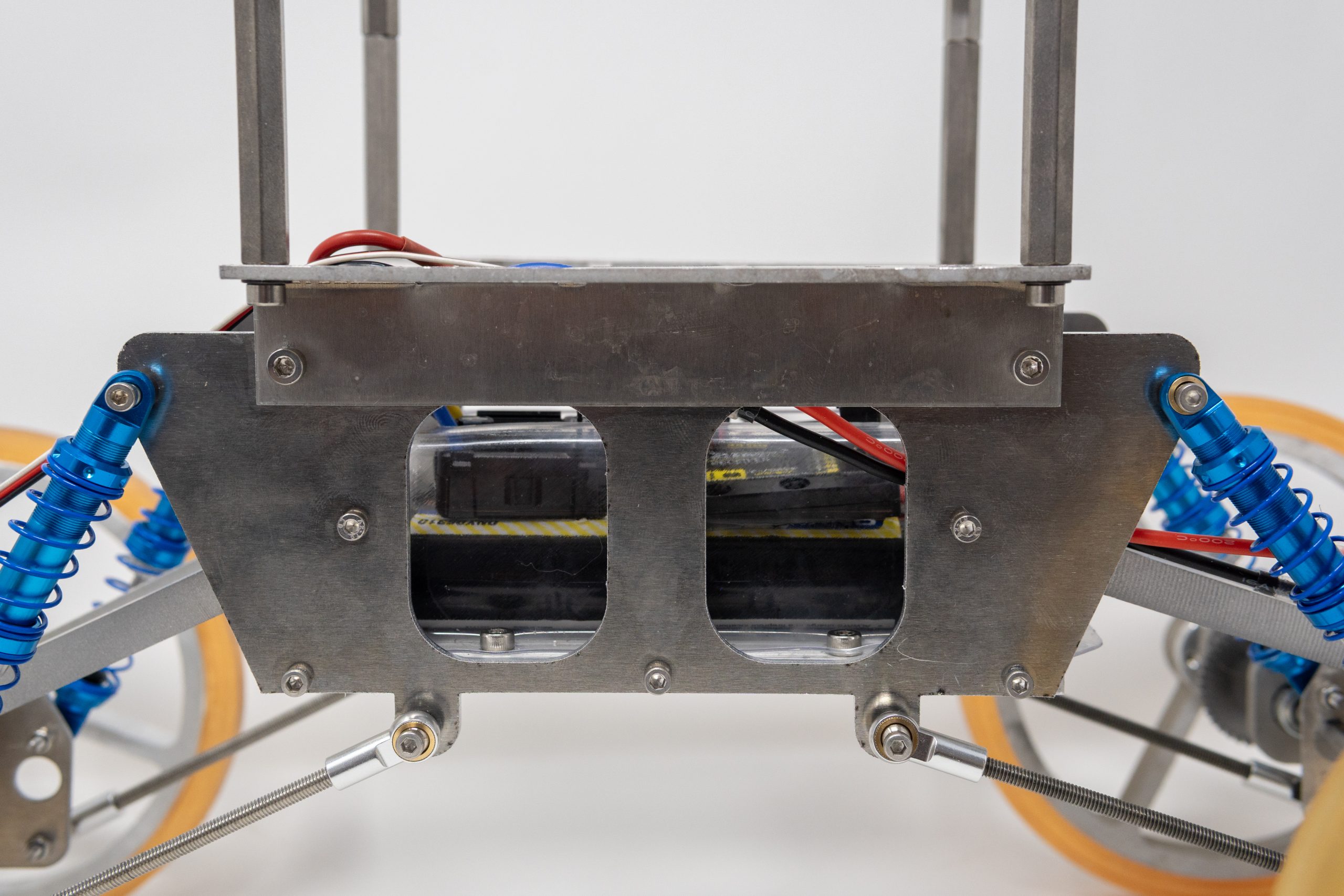

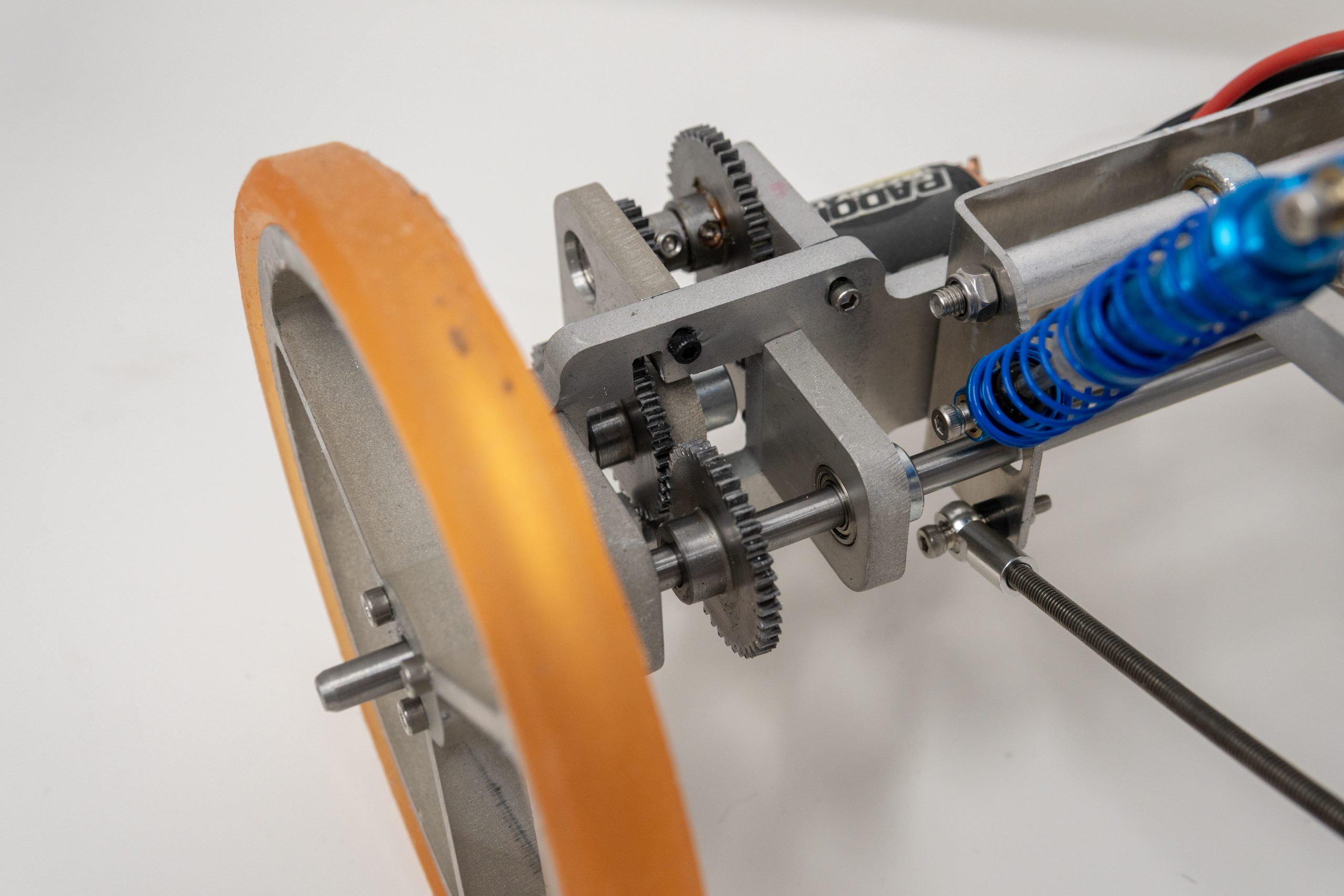

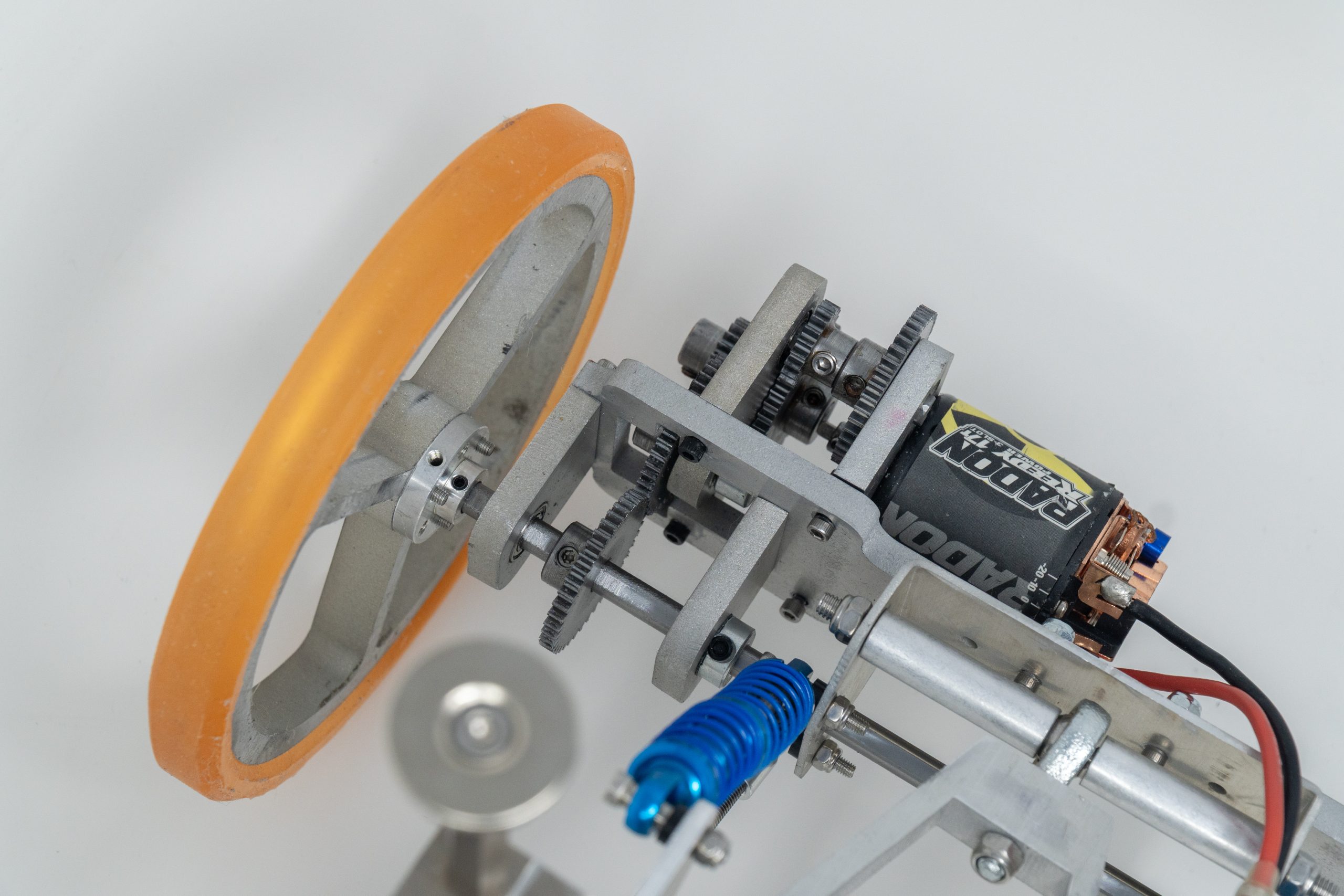

Wheel and tire concepts were validated through hands-on prototyping, including 3D-printed wheel variants and cast test tires made from urethane resins at 30A, 50A, 65A, and 80A hardness. For the tires, the final geometry featured flat sidewalls with a half-rounded top and bottom. A matching undercut profile was machined into the wheel so the tire could snap into the rim and then be glued in place. The tire was also cast slightly undersized, allowing it to stretch over the wheel and tightly grip the rim. This combination significantly improved retention during cornering, as fully flat tire profiles were found to be less reliable and more prone to slipping under load.

Material selection was driven by cost, performance, and manufacturability. While Delrin was considered due to its machinability and low density, aluminum was ultimately chosen for the wheel blanks. Although aluminum is denser than Delrin, its higher stiffness and strength allowed for more aggressive light-weighting, resulting in a wheel that was both lighter and structurally stronger than a thicker plastic alternative. Aluminum sheets also enabled a more efficient production flow, allowing multiple wheel blanks to be waterjet-cut from large sheets in a single operation, minimizing waste and setup time. Compared to other materials, the aluminum sheets were the most cost-efficient at the time.

With the design finalized, planning shifted toward manufacturing execution. While design-for-manufacturing principles were considered early, detailed process development and tooling strategies were addressed after prototyping, as they required access to machines and custom setups that were not feasible during early testing. This separation allowed the team to move quickly through design while still setting up a robust and efficient manufacturing process for full-scale production.

Wheel Manufacturing Process

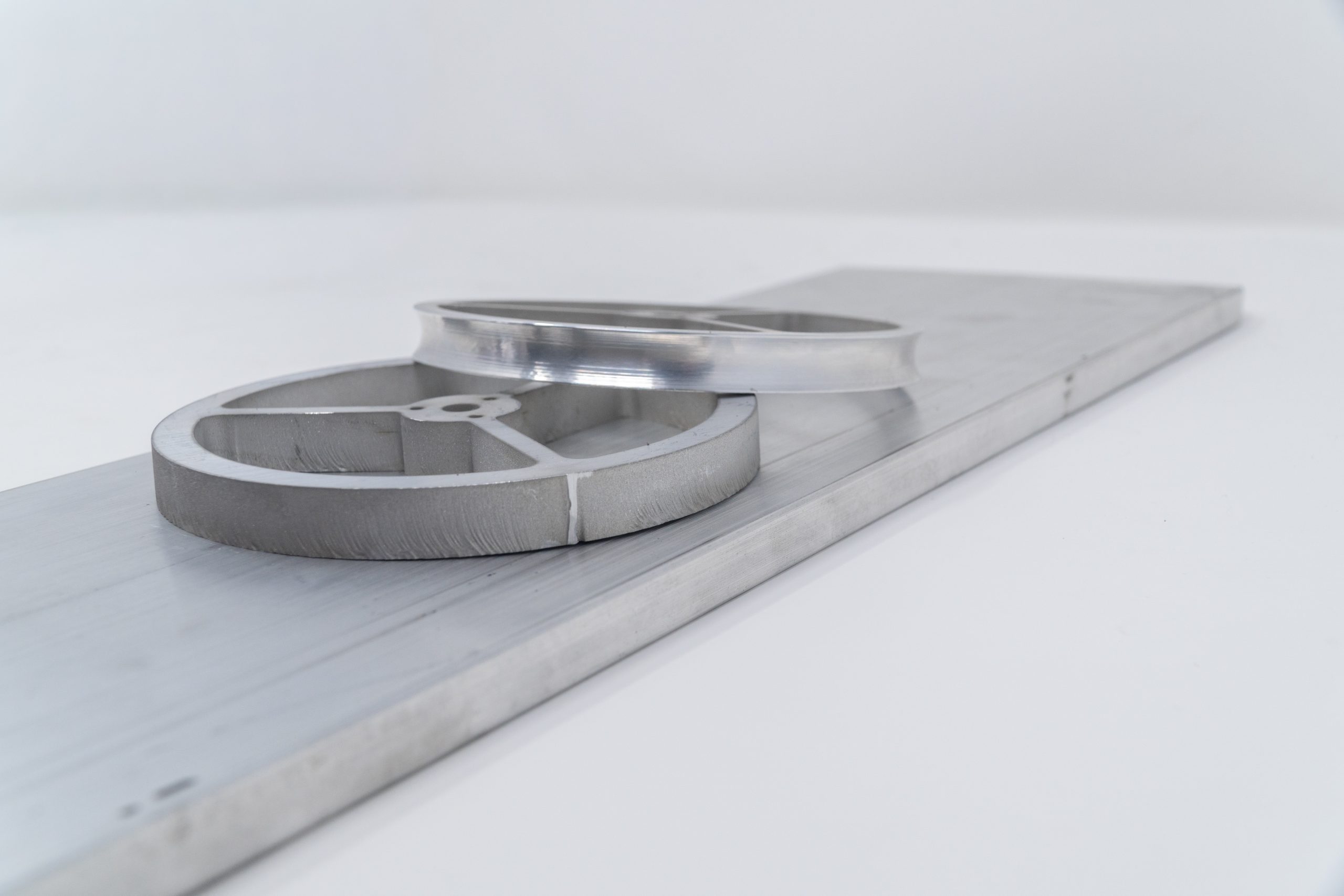

Wheel production began with a 2 ft × 4 ft × 0.5 in aluminum sheet, which was used to generate multiple wheel blanks in a single waterjet operation. The waterjet cut all required internal geometry in one pass, including the spoke cutouts, three bolt holes for hub attachment, and the center bore. Small tabs were intentionally left between each wheel blank and the sheet to prevent parts from falling into the waterjet tank. These tabs were programmed to be thin enough to be manually punched out after cutting.

Once removed from the sheet, the remaining tab material on each wheel blank was sanded flush. This step was important to reduce tool loading and ensure stable fixturing during later machining operations. The bolt holes and center bore were then reamed to final size to account for waterjet taper and to guarantee consistent, repeatable fits across all parts. The center bore was sized at 5/16 in to interface with the custom fixturing used in the lathe, rather than being finished directly for the D-shaft at this stage.

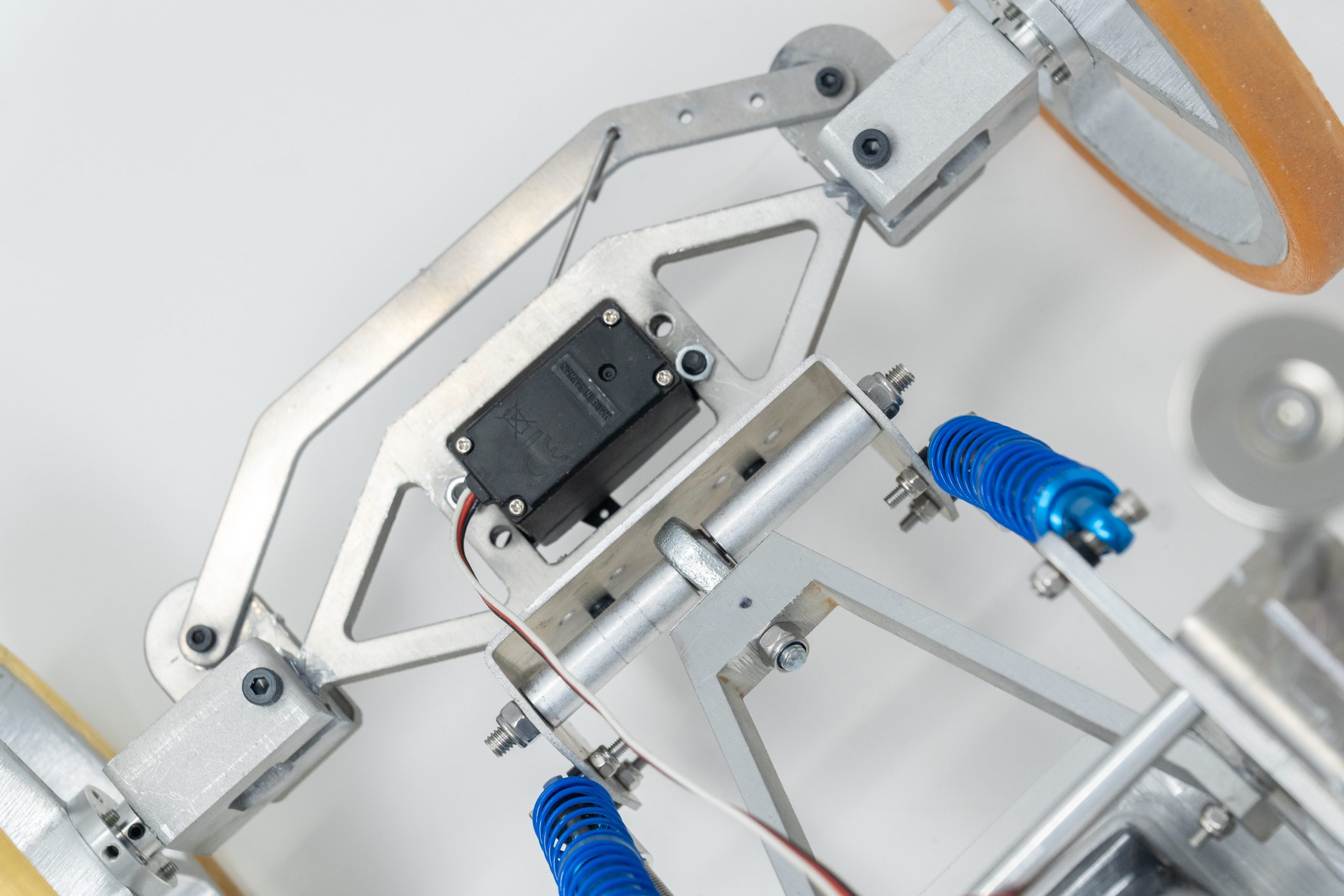

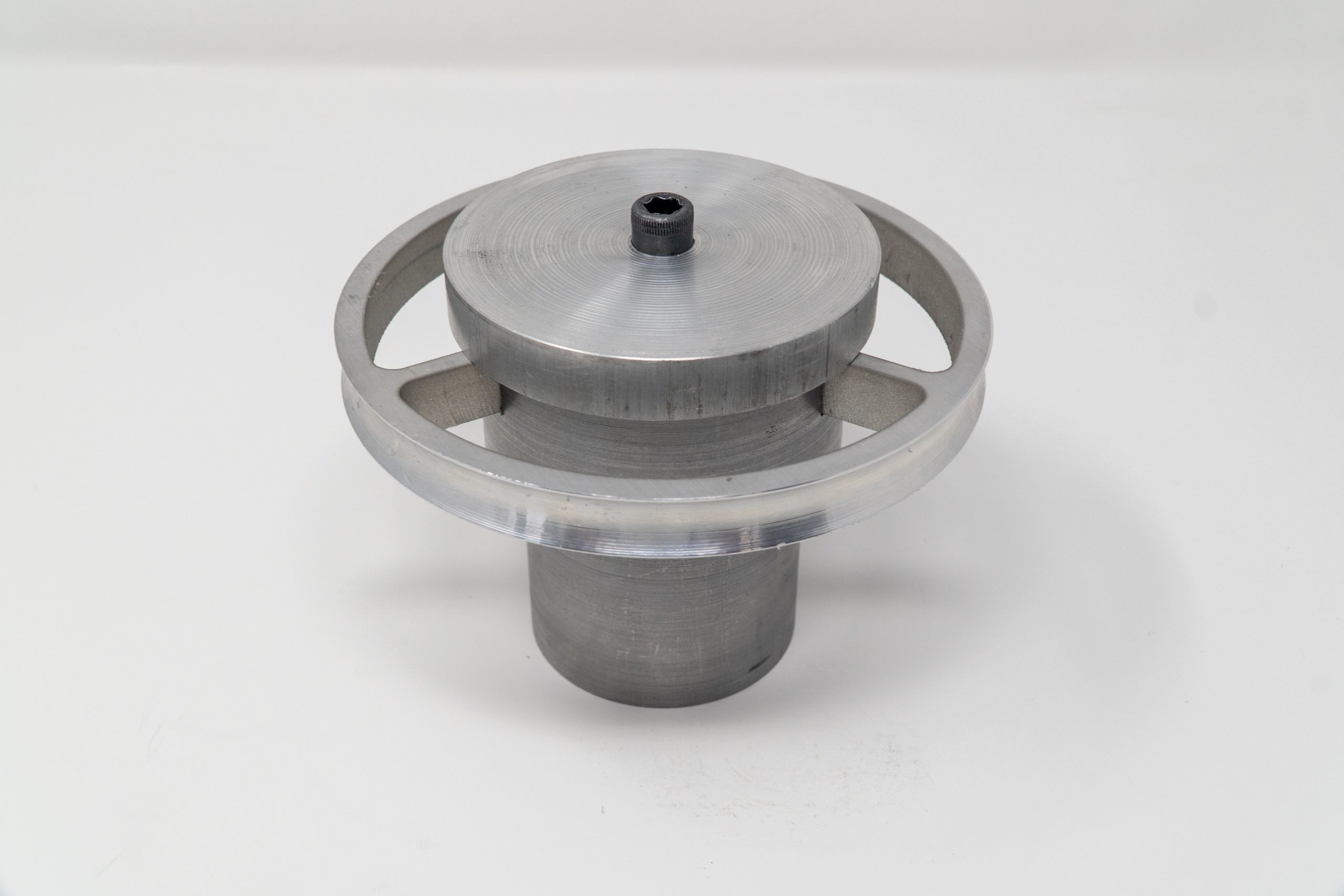

Final shaping of the wheel was completed on a Haas LT1 CNC lathe. I designed and fabricated a custom jig specifically for this process, securely locating each wheel with a single fastener, allowing parts to be swapped quickly while maintaining consistent alignment. You can see the process of making this jig here. This fixture was a key enabler for repeatability and throughput, making it possible to machine all wheels efficiently at scale. The lathe operation cut the outer wheel profile and the circumferential groove that captures the tire, a feature that could not be produced using the two-dimensional waterjet process. The video of the lathe cutting can be seen here.

After lathe machining, the wheels underwent light deburring to remove small edge burrs created by high-speed production. Because slight variations in blank thickness produced inconsistent burr formation, manual deburring was a faster and more reliable solution than attempting to fully eliminate burrs through additional machining passes. At this point, the wheels were considered complete and ready for tire installation and final assembly.

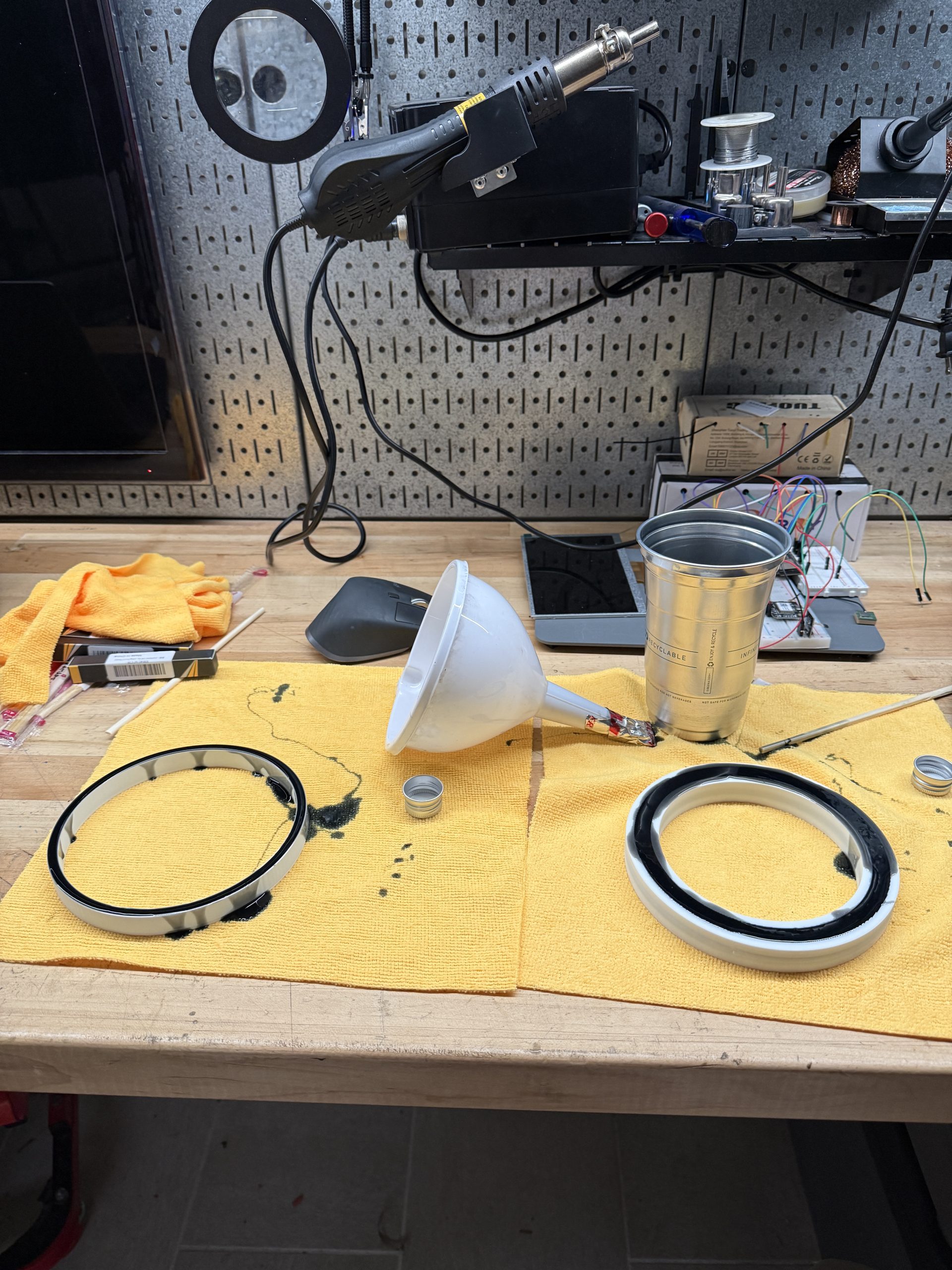

Tire Manufacturing Prosses

Once the tire diameter and profile were finalized, the focus shifted to selecting a manufacturing approach that balanced speed, reliability, and complexity. Two methods were explored: individual tire casting and stacked multi-tire casting. Individual casting was simpler and more robust, but slower, while stacked casting offered higher throughput at the cost of significantly increased setup complexity and risk. Both approaches were evaluated, but at the smaller scale required for this project, the time needed to properly develop a reliable stacked mold outweighed its potential benefits. With sufficient time available, the team opted for individual tire casting and prioritized consistency and repeatability. Click here to see a concept video exploring an early stacked tire mold idea.

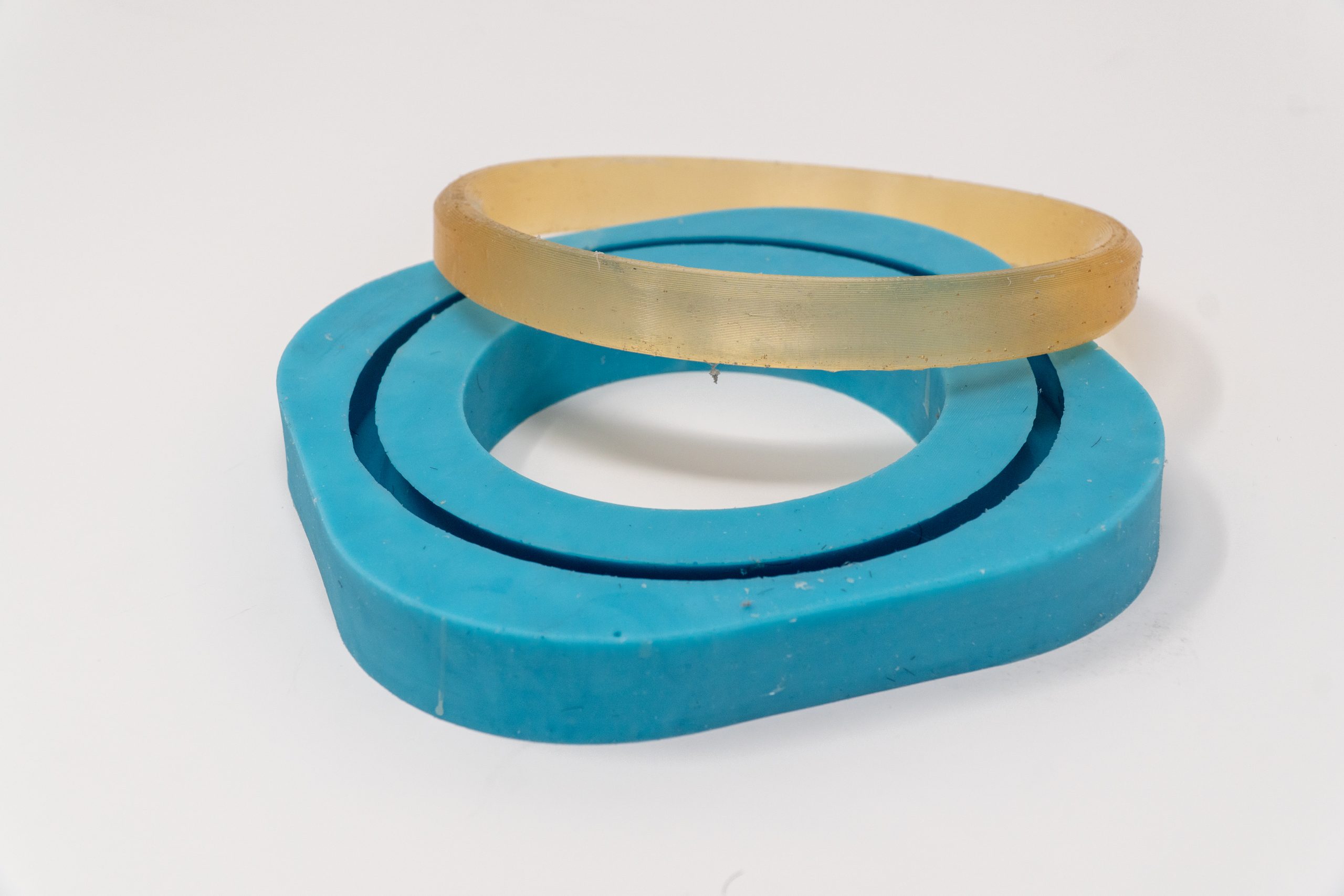

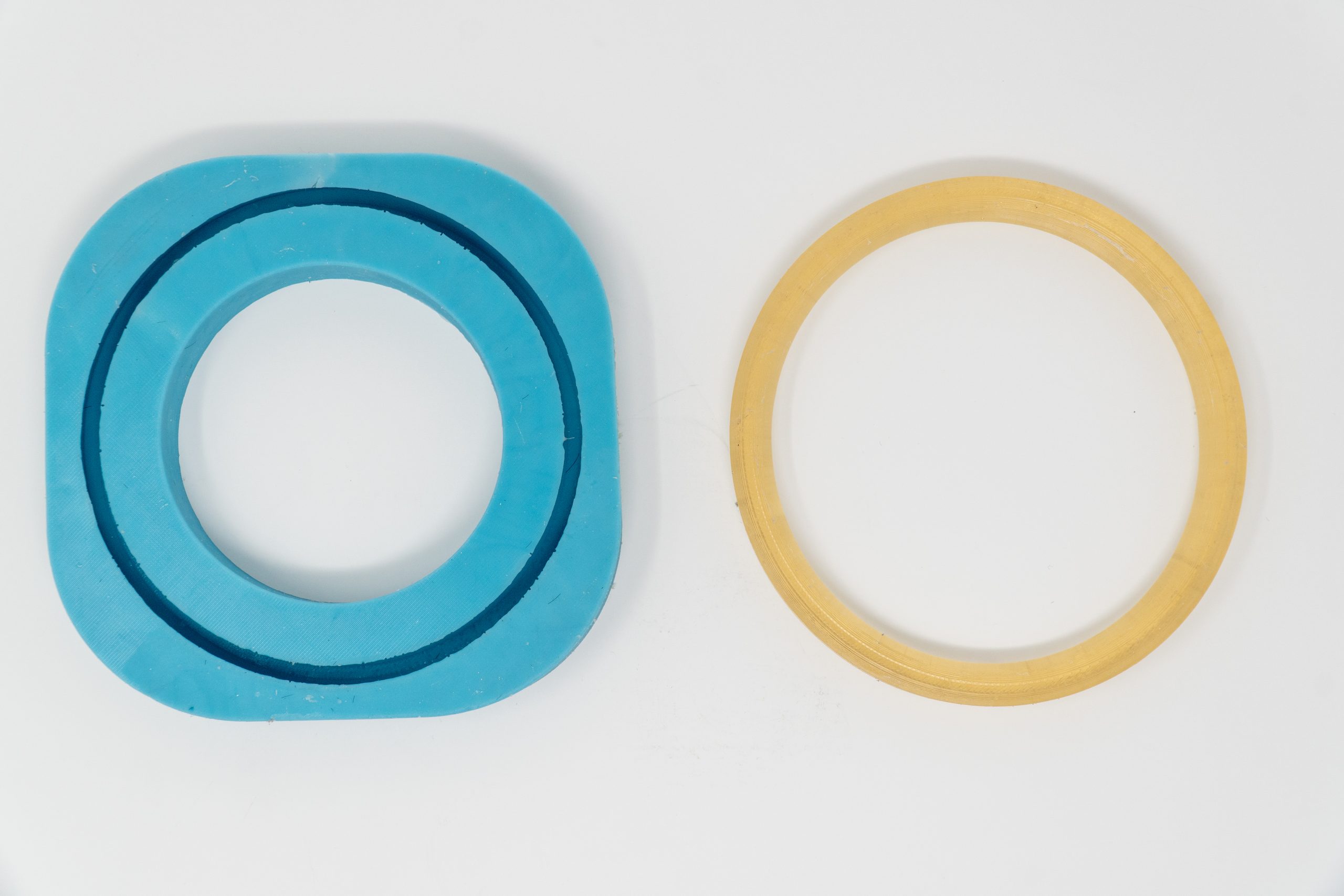

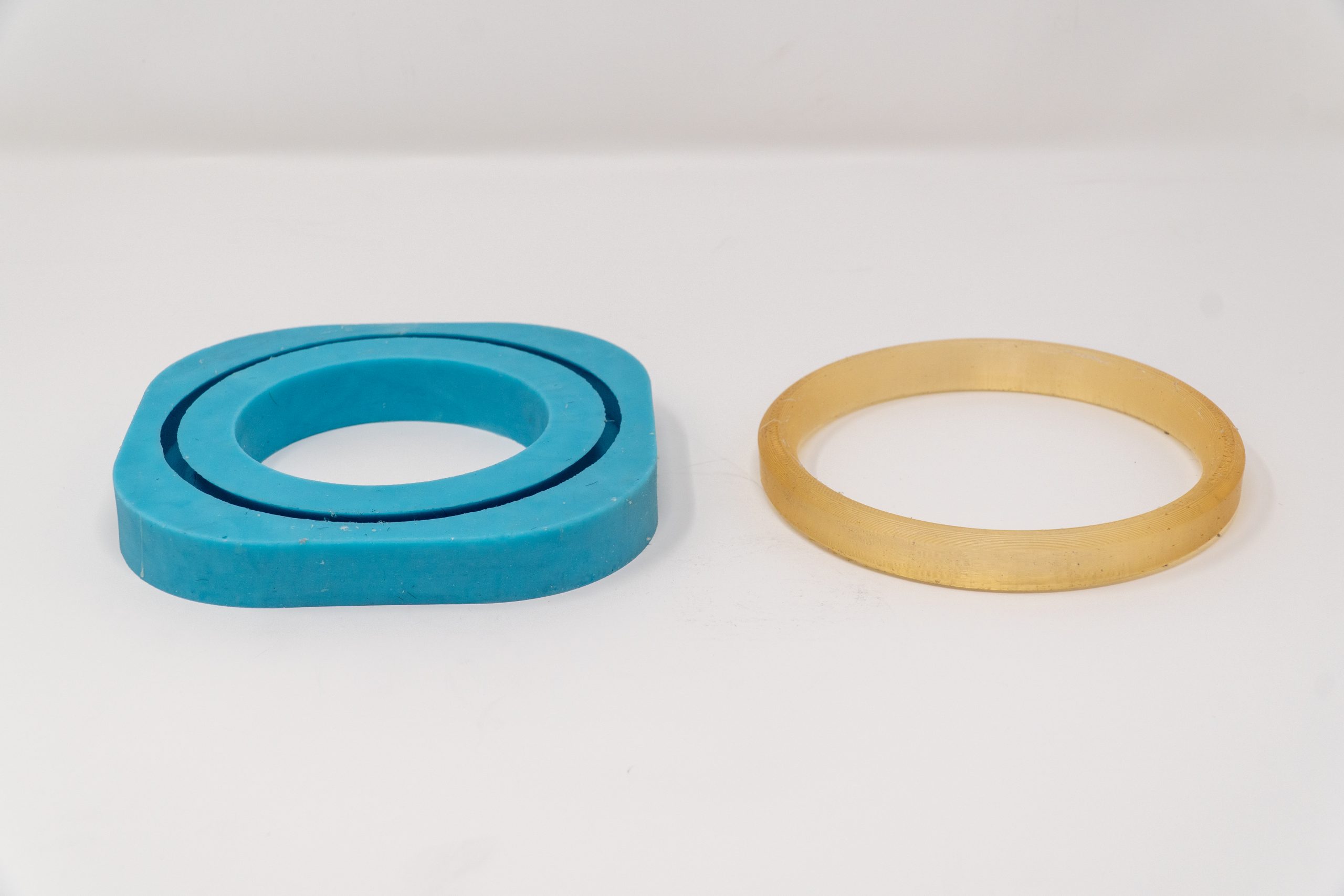

The tire molds were created using a multi-step molding process. A positive 3D-printed tire mold was first produced and used as the master pattern. Silicone was then poured into this mold to create the blue silicone mold shown in the images. Once cured, this process yielded a negative mold of the tire geometry, which could be replicated to produce multiple molds for parallel casting. With the molds complete, two-part urethane was poured directly into the silicone cavities to cast the final tires.

This approach proved to be reliable from the outset, with successful urethane pours achieved on the first attempts. Testing different durometers during earlier prototyping informed the final material choice, allowing the production tires to meet both performance and durability requirements. The individual casting process provided consistent results while keeping the workflow simple and predictable, making it well-suited for the production scale of the project.

D-Shaft Manufacturing Process

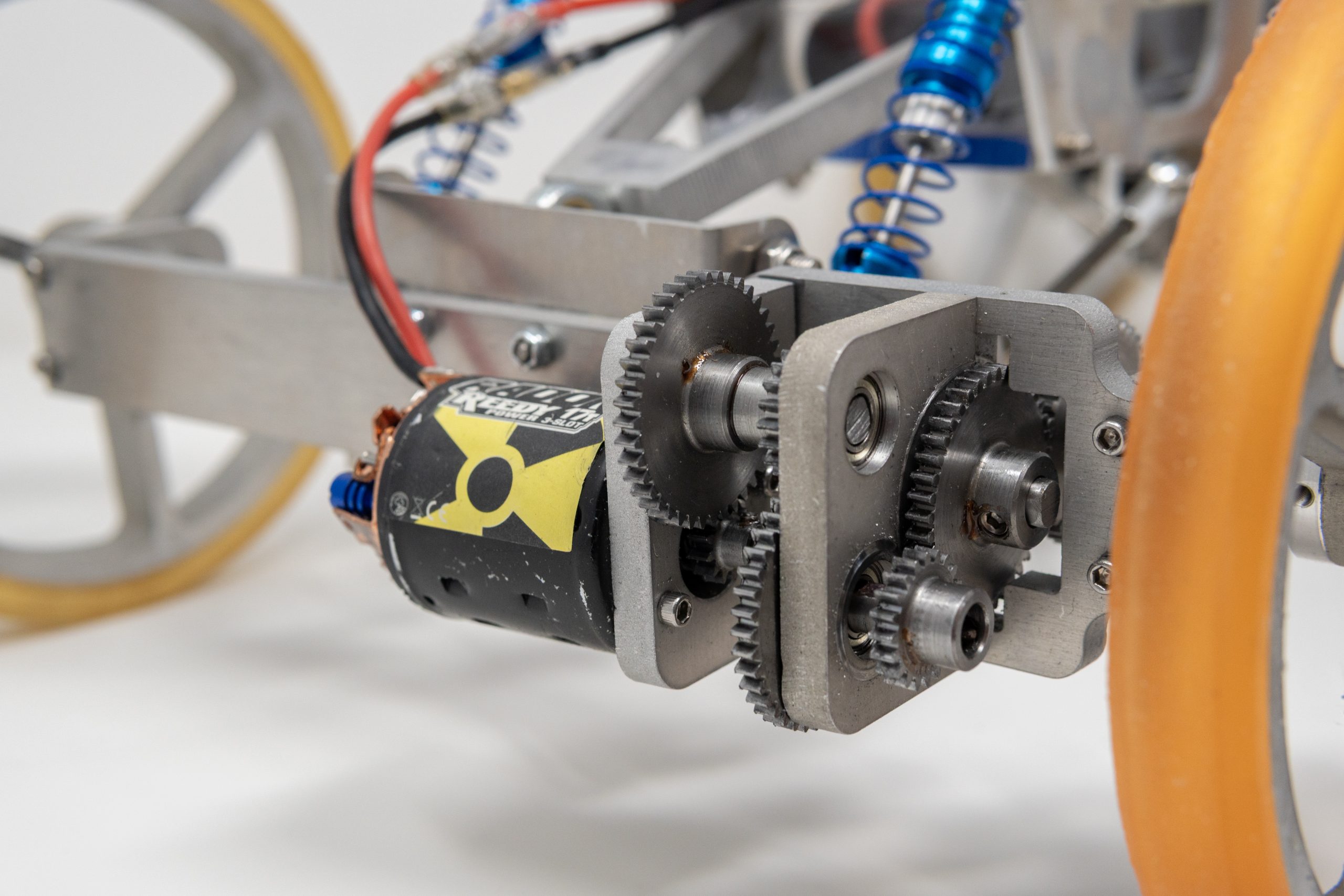

Power from the motor is transferred to the wheels through D-shafts, which interface with hubs that clamp onto the flat face of the shaft. The D-shaped profile prevents rotational play, ensuring the hub, shaft, and wheel rotate together under load. This interface is critical for reliable torque transmission and was standardized across the front and rear of the car, even though the drivetrain itself is rear-wheel drive. Each wheel mounts to a hub, and each hub is secured to the D-shaft using set screws.

Once the D-shafts were cut to length, the remaining challenge was adding precise divots for the set screws to seat into. Without these divots, the set screws would loosen over time, leading to slippage between the hub and shaft. To solve this efficiently at scale, I created a custom drilling jig, as shown in the video to the left. The jig was mounted in a three-jaw chuck on a Bridgeport mill and carefully indicated to ensure it was square and coplanar with the machine’s X and Y axes. The Z-axis was then set to control drilling depth consistently across all shafts.

The jig allowed each D-shaft to be inserted and aligned quickly. An adjustable top screw, ground flat at its contact face, pressed against the flat side of the shaft to ensure it was properly oriented relative to the spindle. This adjustability was critical, as the D-shafts varied slightly in dimension and required individual alignment. Integrated hard stops within the jig defined the axial position of the shaft, allowing two divots to be drilled at precise, repeatable locations. After drilling the first divot, the shaft was repositioned against the second stop and drilled again before being removed and replaced with the next part. This jig eliminated the need to repeatedly locate center and manually align each shaft, dramatically reducing setup time while improving consistency. It enabled fast, repeatable production of all D-shafts and ensured reliable hub retention throughout vehicle operation.

Final assembly

Once both the wheels and tires were completed, each component was thoroughly cleaned to remove machining oil and casting residue before assembly. A clear construction adhesive was selected for bonding the urethane tires to the aluminum wheels, as it provided reliable adhesion between the two materials. The tires were cast slightly undersized, allowing them to stretch and tightly grip the wheel before adhesive was applied, which significantly reduced the risk of slippage under load. Adhesive was applied to the wheel, the tire was snapped into place, aligned, and left to cure. This process was repeated for all 160 wheels, as shown by the assembly batches in the image to the left. In testing and use, the assembled wheels performed as intended, providing consistent grip and reliable performance across varied terrain and obstacles.

Gallery